#Nonwovens / Technical Textiles

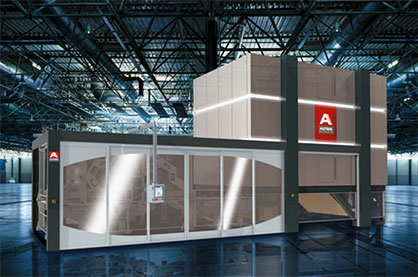

Autefa Solutions, well prepared with highly competitive solutions for CINTE Techtextil 2020

Marco Fano, CMO Autefa Solutions: “There is still a huge demand for Spunlace Lines and our unique web forming technology meets our customers’ requirements. We are positive, our order intake, especially for card- crosslapper combinations, is very good. This advanced Spunlace technology offers a quick return on investments with our customers appreciating the performance and quality of Autefa Solutions Lines. Furthermore, we recently sold several needle punching machines for spunbond applications following request for machines with high production.”

The main challenge in high-speed webforming lines for Spunlace is to keep fibers at any time and process stage under control. Autefa Solutions Injection card enables (Drylaid) web forming at very high production. The Injection Card uses a combination of mechanical and aerodynamic principle for a gentle fibre treatment. The Injection Card delivers a quality web at the highest productions with a better MD/CD. With the Topliner CL4006 SL Autefa Solutions offers a crosslapper with special features for the Spunlace application. Highest layering speeds and precise weight distribution are possible thanks to the integrated drafting unit, compensation belt, antistatic equipment and new designed transport aprons.

With the Hydroentanglement Machine V-Jet FUTURA Autefa Solutions recently closed the missing link within the companies’ product portfolio between the very successful Autefa web forming technology and the drying technology. The Hydroentanglement Machine V-Jet FUTURA and the Square Drum Dryer SQ-V, stand for an advanced technology. This new technology offers a significant reduction of energy consumption compared to any state-of- the-art line.

Autefa Solutions Square Drum Dryer SQ-V combines the advantage of a horizontal belt dryer and the better drying efficiency with the space advantage of a drum dryer, resulting in increased drying length with small footprint.

Marco Fano: “Our Technology Center in Linz, Austria offers four nonwovens productions lines with several bonding technologies (needling, thermobonding, hydroentanglement) and a special line for Carbon fiber processing. We are currently running customer trials on the latest Spunlace line at our Linz facility and also providing a special service using video camera technology for our customers that cannot travel to Austria at the moment. We look forward to holding our open- house event in Linz in 2021.“

Autefa Solutions offers a wide product range of Needle Punching machine including Stylus single- and double-board needle looms, tandem needle looms, velour-, structuring and patterning needle looms as well as needle Autefa Solutions, well prepared with highly competitive solutions for CINTE/Techtextil 2020 looms for paper maker felts. Autefa Solutions delivers needle looms from 1 m up to 16 m working widths. Thebroad portfolio leaves nothing to be desired in terms of any needling felt applicationDuring CINTE/Techtextil in Shanghai Autefa Solutions presents future-proof solutions for improving quality and productivity. The company presents its portfolio as a preferred full- line supplier for carded- crosslapped needlepunch lines, aerodynamic web forming technology, spunlace, and thermobonding lines for producing nonwoven to cater to wide range of applications such as Hygiene, Wipes, Filtration, Geotextile, Automotive, Carpets, Technical felts, Wadding, Insulations, etc. In the premium nonwoven segment Autefa Solutions has a comprehensive product range in both forming and bonding systems. Combining the experience of the companies AUTEFA, Fehrer, FOR and Strahm the company stands for high quality, durability and performance.