#Nonwovens / Technical Textiles

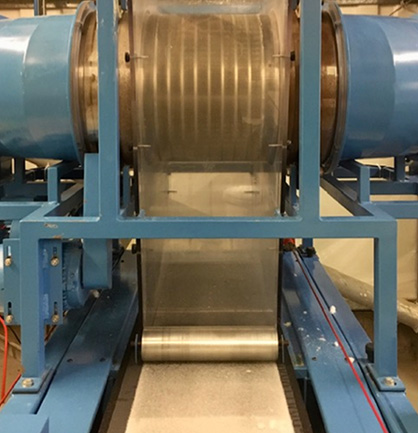

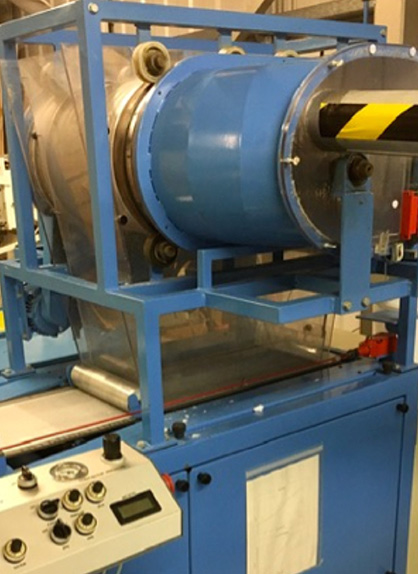

Expansion of prototyping facilities for NIRI with investment in airlaid technology

Airlaying refers to a family of dry-laid web formation processes used in the manufacture of disposable, single-use products and durable products. The general properties of airlaid fabrics are high isotropicity; high loft (if required); high porosity (95-99%); high absorbency and wicking rate; soft handle; adequate tensile strength; good resilience (compression recovery); and high thermal resistance. These properties make airlaid nonwovens the ideal materials for medical textiles, hygiene and feminine products, nappies and wipes, meat pads, filters, insulation felts and automotive filters.

Sustainability was a key factor in NIRI’s investment in airlaid prototyping equipment, as Dr Matt Tipper, business director at NIRI explains,

“With the EU Directive on single use plastics, the nonwovens industry is focused on experimenting with processes that work towards increased sustainability. Manufacturers are exploring airlaid technologies as these use a high percentage of natural fibres - predominantly fluff pulp which is both cost-effective and sustainable, biodegradable and renewable.”

Having worked with more than 200 companies to develop and improve over 450 products, to-date, NIRI’s investment in new airlaid equipment will be of particular benefit to clients in the medical and hygiene sectors – producing and improving products where airlaid technology is most used. Additionally, as borne out by market intelligence gathered over recent years, filtration industries and sectors such as automotive are revisiting airlaid technology – reducing the reliance on synthetics and improving sustainability.

Matt continues,

“In combination with NIRI’s other carding, spunmelt and wetlaid web formation lines as well as chemical, thermal, hydroentanglement and needlepunch bonding capability, we have the ideal pilot-scale facilities for prototyping products across a plethora of industries with a host of end users, as well as the research and commercial expertise to help clients including medical, hygiene, geotextiles, automotive, insulation and filtration, increasing the speed to get products to market.”