#Nonwoven machines

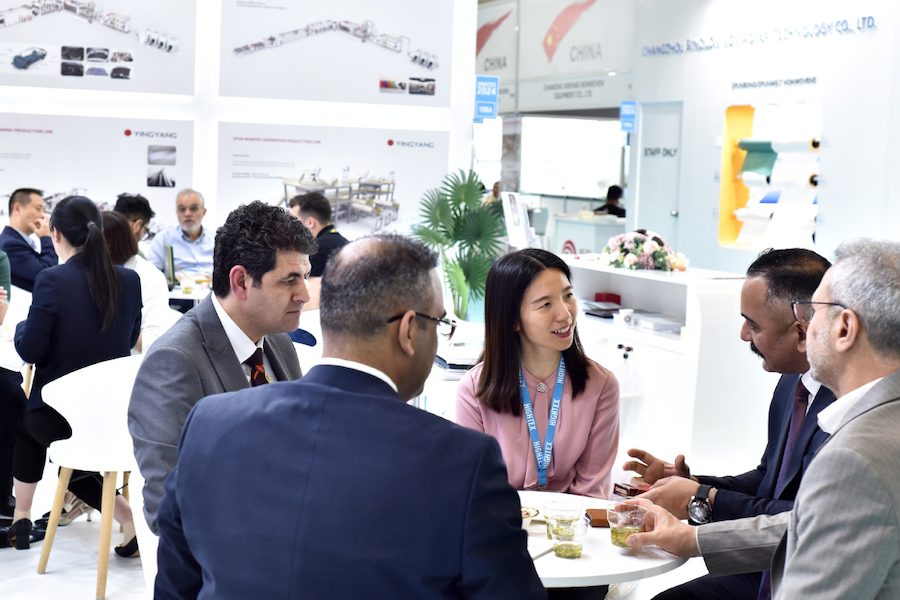

The Nonwovens Institute (NWI) at North Carolina State University and Oerlikon Nonwoven

Cooperation in the field of meltblown laboratory technology

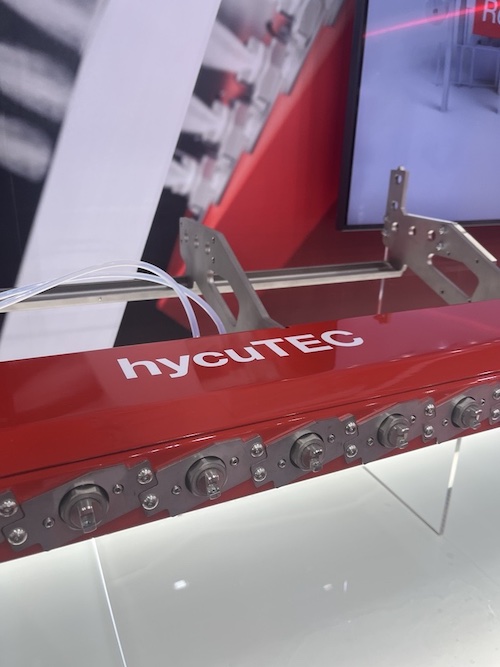

The first step in the new cooperation is an investment in the hycuTEC hydrocharging system from Oerlikon Nonwoven; the institute will integrate the unit into its existing laboratory configuration. This will enable the NWI to operate a state-of-the-art meltblown hydrocharging laboratory in the future, facilitating the development of new products – primarily, but not exclusively, in the field of air filtration media. The advantage for North American Oerlikon Nonwoven customers and prospects is that they will be able to test hycuTEC technology and carry out their own meltblown product developments in a creative, innovation-oriented environment.

Oerlikon Nonwoven's patented hycuTEC system is a real innovation for the filtration industry. Using a special spray mist of demineralized water, the system enables the economic production of highly efficient electret-media with an impressive filtration efficiency of 99.99% at low pressure-drop. The hycuTEC hydrocharging technology was honored with the Edana Filtrex Innovation Award in 2023.