#Market Analysis & Forecasts

Polypropylene Nonwoven Fabric Market Report 2023: Sector to reach $42.29 Billion by 2030 at a 6.5% CAGR

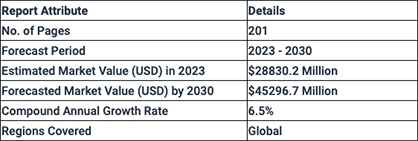

The global polypropylene nonwoven fabric market size is expected to reach USD 45,296.7 million by 2030 and is expected to expand at 6.5% CAGR from 2023 to 2030. This market growth can be attributed to rising civil engineering, agricultural, and transportation activities in North America.

In addition, polypropylene nonwoven fabrics are rising product demand in end-use industries including hygiene, medical, automotive, agriculture, and furnishing. High demand for polypropylene fabrics in the hygiene industry for manufacturing sanitary products for babies, women, and adults is likely to drive industry growth.

Polypropylene (PP) is the majorly used polymer in the production of nonwoven fabrics followed by other polymers such as polyethylene, polyester, and polyamides among several others. PP is a relatively inexpensive polymer and offers the highest yield (fiber per kilogram). Furthermore, PP has the highest versatility and lowest specific gravity for nonwoven fabrics. However, the prices of polypropylene are highly dependent on commodity prices and the market has a large number of regional and global players. The major players manufacturing PP are actively investing in advancement through the modernization of R&D and production assets.

Polypropylene nonwoven fabrics are majorly employed in personal hygiene products including baby diapers, sanitary napkins, training pants, wet and dry wipes, cosmetic applicators, tissues, adult incontinence products such as top sheets, back sheets, stretch ears, fastening systems, core wrap among several others. PP fabrics offer excellent absorption, softness, stretchability, strength, tear resistance opacity, and breathability. Thus, it is majorly used in hygiene products.

Spun-bonded technology dominated the polypropylene nonwoven fabric market contributing toward a major share of total market volume in 2022. Low cost and easy production process associated with this technology have been the key factor for higher market share for these products. The demand for meltblown and composite products is expected to grow in geotextiles and industrial applications on account of their high moisture barrier and high strength properties. However, high costs associated with melt-blown polypropylene nonwoven fabrics are expected to hamper their market growth over the projected period.

The polypropylene nonwoven fabrics industry is highly competitive owing to the presence of numerous manufacturers. The companies in the market invest highly in R&D to improve the quality and reduce the weight of polypropylene products. High production capacities, a wide distribution network, and goodwill in the market are key factors that offer a competitive advantage for multinationals in this business. The companies in the market use mergers and acquisitions and capacity expansion strategies to strengthen their position in the competitive market.

Europe accounted for the largest share of the market in 2022. However, Asia is expected to emerge as one of the leading regions in the baby diapers market over the forecast period. Owing to the high demand for spun-bonded nonwovens for baby diapers in Asia, a number of companies such as Toray Industries, Schouw & Co., Asahi Kasei Corporation, Mitsui Chemicals have expanded their manufacturing capacities in Asia to respond to the local demand. The aforementioned factors are expected to fuel the growth of the polypropylene nonwoven fabric industry.

Polypropylene Nonwoven Fabric Market Report Highlights

- Meltblown polypropylene nonwoven product segment is expected to dominate the industry with a growth rate of 6.2% from 2023 to 2030. The microfibers in meltblown products have a circular cross-section, and smooth surface texture, which offers them filtration characteristics, softness, and high surface area for excellent insulation

- Superior barrier properties, good wicking properties, and enhanced filtration efficiency offered by polypropylene melt-blown fabrics are expected to propel their demand in liquid absorption, insulation, and filtration applications

- Staples polypropylene nonwoven fabrics are gaining importance in medical applications over any other PP fabrics on account of their finer filtration and low-pressure drop properties. Increasing staple PP nonwoven penetration in medical applications such as gloves, medical packaging, surgical gowns, masks, drapes, and covers is expected to augment the market growth. Surgical drapes, gowns, and masks are expected to be primary products driving the demand for staples polypropylene nonwoven fabrics

- The hygiene application dominated the market with a 55.9% of revenue market share in 2022. Disposable and absorbent nonwoven fabrics have become an important part of the daily life of consumers. Improved consumer lifestyle and increasing consumer preference towards skin health are the key factors driving the demand for nonwoven fabrics in hygiene applications

- Polypropylene nonwoven fabric materials offer excellent smoothness, softness, comfort, stretchability, fluid-barring capacity, and absorption as compared to traditional textiles, thus gaining high demand for manufacturing hygiene products

- Polypropylene nonwoven fabrics are used for manufacturing coated cloth, display felts, tapes, conveyor belts, cable insulation, air conditioner filters, semiconductor polishing pads, noise absorber felt, etc. in industrial applications. Increasing investment in the industrial sector across the developing economies of the world including China, India, and Brazil is expected to have a positive impact on the polypropylene nonwoven fabrics industry growth over the forecast period

Key Topics Covered:

Chapter 1. Methodology and Scope

Chapter 2. Executive Summary

Chapter 3. Polypropylene Nonwoven Fabric Market Variables, Trends & Scope

Chapter 4. Polypropylene Nonwoven Fabric Market: Product Estimates & Trend Analysis

4.1. Definition & Scope

4.2. Polypropylene Nonwoven Fabric Market: Product Movement Analysis, 2022 & 2030

4.3. Spunbounded

4.4. Staples

4.5. Meltblown

4.6. Composite

Chapter 5. Polypropylene Nonwoven Fabric Market: Application Estimates & Trend Analysis

5.1. Definition & Scope

5.2. Polypropylene Nonwoven Fabric Market: Application Movement Analysis, 2022 & 2030

5.3. Hygiene

5.4. Industrial

5.5. Medical

5.6. Geotextile

5.7. Furnishing

5.8. Carpet

5.9. Agriculture

5.10. Automotive

5.11. Others

Chapter 6. Polypropylene Nonwoven Fabric Market: Regional Estimates & Trend Analysis

Chapter 7. Competitive Landscape

Chapter 8. Company Profiles

Companies Mentioned

Kimberly-Clark Corporation

Berry Global, Inc.

Lydall, Inc.

First Quality Nonwovens Inc.

PFNonwovens a.s.

Schouw & Co.

Mitsui Chemicals Inc.

FITESA

Toray Industries Inc.

Freudenberg Group

Ahlstrom-Munksjo Oyj

Johns Manville Corporation

Souminen Corporation

Asahi Kasai Corporation

For more information about this report visit:

https://www.researchandmarkets.com/r/d6g1wt