#ITMA Asia + CITME 2024

STOLL pushes the flat knitting industry in China

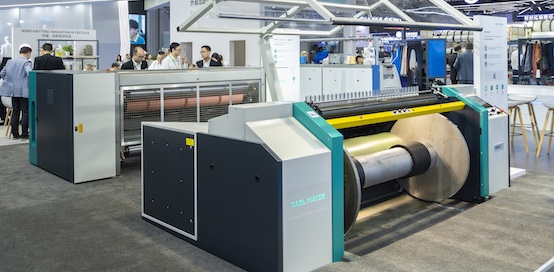

The event at KARL MAYER (CHINA) started on the day before the trade fair and was attended by a small, but very good audience. Around 140 visitors, mainly with technical and management responsibility, were welcomed. A special highlight awaited the guests from the flat knitting industry: at the start of the in-house show, a new showroom was opened with solutions from all technology areas, but above all with a central TexLab from STOLL.

The ITMA ASIA + CITME 2024 event marked the premiere of the in-house show format for STOLL customers in China.

“This was the first time for Stoll to arrange a in house show this idea needs to be further developed although in general the response was very positive,” says Rene Ludvigsen, Chief Sales & Product Asia at STOLL, summing up. The TexLab in particular was a crowd-puller.

Great interest in the TexLab from STOLL

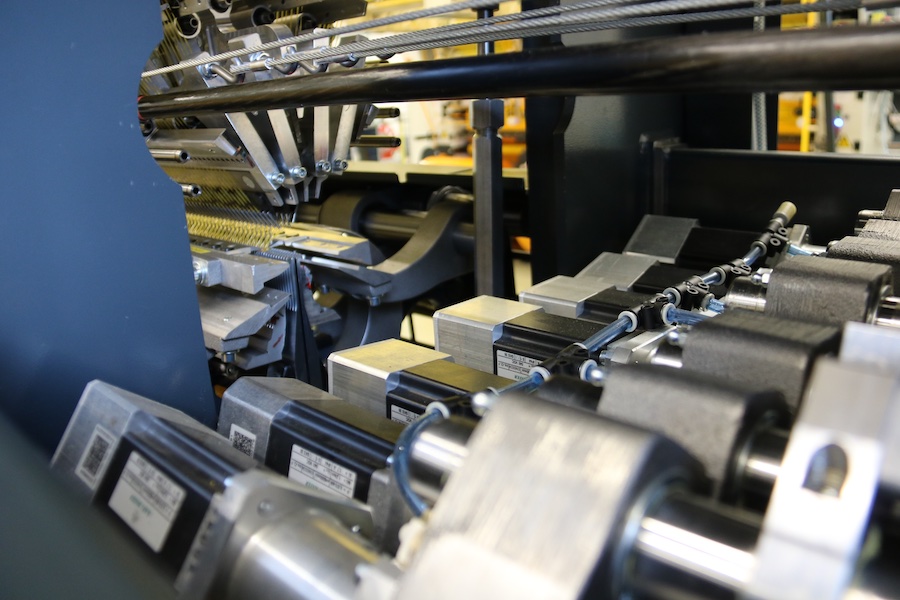

The TexLab for the flat knitting industry is an exhibition space, meeting point and experience centre. It offers everything needed to make contacts and develop concepts, try out new yarns and develop innovative patterns. The TexLab includes modern machinery, textile innovations full of inspiration, futuristic fashion items, such as the latest STOLL Trend Collection, and an experienced team of STOLL application technicians. The concept was convincing, the design and in particular the general equipment were impressive. “The different STOLL machines in various gauges and the new sample collections that were created on them, were certainly the highlight of the in-house show,” says Rene Ludvigsen.

High quality of discussions

The experienced manager was delighted with the numerous in-depth technical discussions. The top topics included proven STOLL technologies such as knit and wear®, but also the high machine gauges for which STOLL is known. For the development of fine, high-quality articles, the STOLL TexLab was equipped with a CMS 530 in the new gauge E20.

In the course of the in-house show, Rene Ludvigsen and his team were able to sign various contracts and launch new projects for the coming years. He also learnt more about future developments in the flat knitting sector through discussions with customers. “The main trends are towards digitalisation, smart factories, AI technologies and the production of knit and wear items,” explains Rene Ludvigsen.

Customers are looking for innovations and are generally optimistic, but are concerned about the high price pressure in their markets. Own brands and the players in the cashmere business are less affected by this and can expect stable growth in the coming years.

STOLL will continue to support them all with its expertise, innovative machines and useful service solutions.