#ITMA Asia + CITME 2024

New double raschel machine impresses with its price-performance ratio

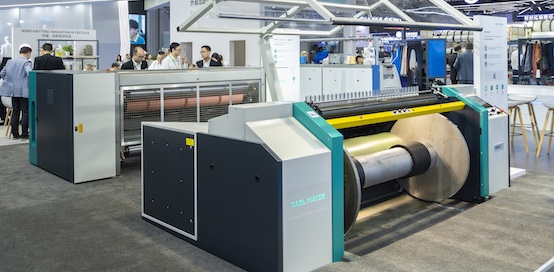

KARL MAYER has further differentiated its range of double raschel machines and thus better tailored them to market requirements. The DM 6/2-6 EN is a new addition to the family of high-performance machines for the production of spacer fabrics. With a speed of 850 rpm, this newcomer offers the same working speed as its range neighbours, the RD 6/1-12 EN and RD 7/2-12 EN. However, thanks to its special technical focus on the production of lightweight 3D warp-knitted fabrics, it is significantly lower in price. The configuration on offer includes a trick plate distance of 2 to 6 mm and a working width of 138? making the DM 6/2-6 EN ideal for the highly efficient production of spacer fabrics for the luggage and furniture sector. The flexible RD 6/1-12 EN is still the machine of choice for the production of technical spacer fabrics for home textiles and plush applications, while the RD 7/2-12 EN sets standards in the production of 3D articles with a wide range of designs for shoes and automotive applications.

If you want to see the performance of the DM 6/2-6 EN for yourself, you should visit the in-house show during the upcoming ITMA ASIA + CITME at KARL MAYER (CHINA) in Changzhou. This is where the new double raschel machine will celebrate its premiere.

The event begins on 13 October with the opening of the KARL MAYER GROUP's new showroom and, in addition to the new double raschel machine, has six other machine highlights and numerous textile innovations in store for visitors.