#Knitting & Hosiery

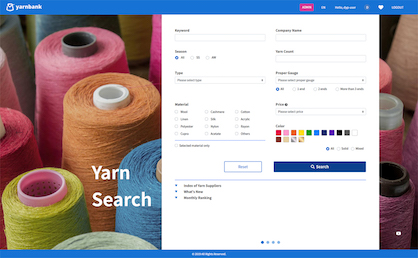

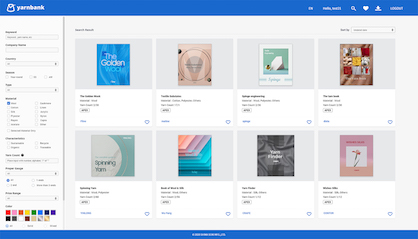

SHIMA SEIKI announces opening of digital yarn sourcing website

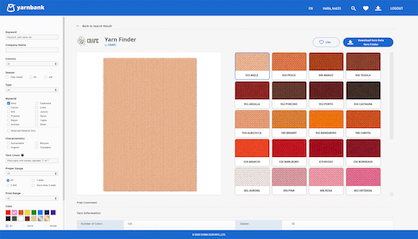

Users can also download yarn data for free, for use in fabric simulation and virtual sampling on SDS®-onE APEX4 design system as well as APEXFiz™ subscription-based design software likewise

announced last month. Users can thereby avoid the need to scan yarn on their own. By using yarn that is available for actual production, users can further rest assured that their simulations created using yarnbank™ are not merely realistic images but accurate representations using yarn that can actually be purchased and used in production. Such clear communication is possible with yarnbank™ by bringing together each player in the supply chain—spinner, knit manufacturer and apparel company—and connecting them digitally to eliminate trial-and-error sample making that is the legacy of obsolete analog fashion production.

With its design system and software, SHIMA SEIKI has traditionally promoted design simulation and virtual sampling as an essential part of its “Total Fashion System” concept wherein virtual samples replace physical samples in an effort to reduce time, cost and materials wasted in the sample making phase, further realizing overall efficiency and reduced waste for a sustainable manufacturing supply chain. now, with the launch of yarnbank™, virtual sampling on SHIMA SEIKI design software provides even more effective digital transformation (DX) for the fashion industry.

Registration is free to APEX users, while yarn companies can choose from different plans for registering their yarn on yarnbank™. For yarn companies, yarnbank™ serves as a brand-new promotional platform with the opportunity to present their yarns directly to their customers. In that respect, yarn companies can reduce their dependence on traditional sample books as a means to promote their products, saving time, cost and material and doing their part for sustainability.