#Knitting & Hosiery

Success breeds success

A high demand for the LACE.EXPRESS has led to the development of the new OJ 83/1 B

Companies new to the technology of KARL MAYER’s electronic raschel machines are among its clients, as well as long-term partners, who are placing follow-up orders, and companies who are changing over from using machines produced by other manufacturers.

Encouraged by the first representative of the Lace.Express range, KARL MAYER has now extended this range of machines, for which there is a high demand. The new machine is giving customers the opportunity to use the technology of this innovative machine series to produce fabrics for outwear and underwear. This dual expansion was triggered by feedback on the OJ 59/1 B from the market.

Same speed, more patterns

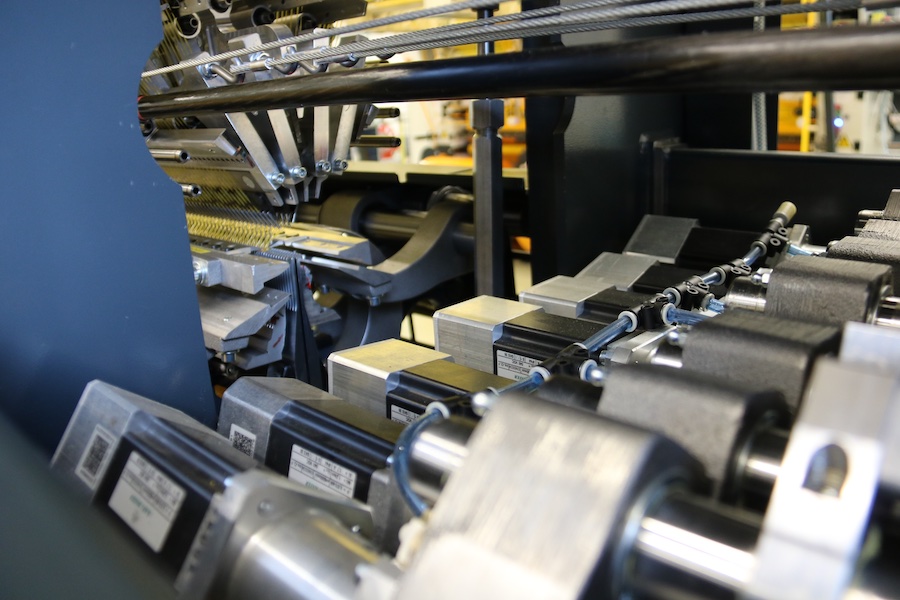

The latest edition of the Lace.Express range is the OJ 83/1 B. It is available in gauges E 18 and E 24, has a working width of 210", and can reach the same high operating speed as the OJ 59/1 B. However, increasing the number of guide bars compared to the first Lace.Express machine means that more patterns can now be produced. In particular, being able to work picot patterns also makes the new machine interesting for producers of tapes and ribbons for intimate apparel. Stylish outerwear fashions, as well as sophisticated lingerie, can also be produced from the lace goods manufactured on the OJ 83/1 B. By using thick yarns, the new machine can also work structured patterns. Up to 32 pattern bars are available for processing yarns to produce a wide range of designs.

Unbeatable productivity and profitability

The new lace raschel machine is far superior compared to reference machines having a large number of guide bars on the market. Extensive experience gained with using the machine in practice has shown that the output of the OJ 83/1 B is 44% higher and the figure is similar for profitability when producing apparel lace. The OJ 59/1 B already has an excellent cost:benefit ratio. This has been proven on the market and also applied to the OJ 83/1 B.

This new machine from KARL MAYER is also efficient in terms of its energy consumption. The OJ 83/1 B consumes up to 40 % less energy compared to other reference machines on the market. KARL MAYER’s LEO® system is behind this considerable reduction. The basic design takes into account the technical concepts of tribology, the pneumatic systems, and the drives for yarn feed, fabric take-down and batching. By optimising the construction, energy losses can be minimised and energy can be utilised more efficiently.

In terms of its ergonomic features, the new OJ 83/1 B also benefits from the high standards typical of KARL MAYER - in particular, the movable Operator Interface, hinged stitch comb bar, easy access to all the drives, a new creel design and an optional, integrated LED lighting system make working a pleasure and operating the machine is mere child’s play.

The market is impressed by the exceptional performance of the OJ 83/1 B. It was only released for sale in October 2017, but the first orders have already been taken - with delivery scheduled for 2018. This new machine was constantly surrounded by people during its first public unveiling at an in-house show held at KARL MAYER (CHINA) from 23 to 25 November. “Shortly after the launch, our sales organisation took orders from both inside and outside China, which is an important indication that the success we have enjoyed so far will continue,” says Jan Hippich, the Head of Product Portfolio at KARL MAYER.

Technical details

The new OJ 83/1 B belongs to the LACE.EXPRESS machine series, which complements KARL MAYER’s repertoire of lace machines, which includes the JACQUARDTRONIC® LACE, TEXTRONIC® LACE, MULTIBAR LACE and LEISUREE.FASHION machines.

The new machine has 14 shog rows, of which 10 are fitted with eight pattern bars for creating the fabric design. The technical features also include the jacquard system of the usual high quality. The fabric produced is wound up by free-standing batcher no. 51. The creel configuration is made up of creels with 16 tiers to create the optimum conditions for loading the bobbins. The machine is available with 30 repeats as standard.