#Industry 4.0 / Digitalization

SABIC launches pilot blockchain project to advance emissions tracking & reductions across value chains

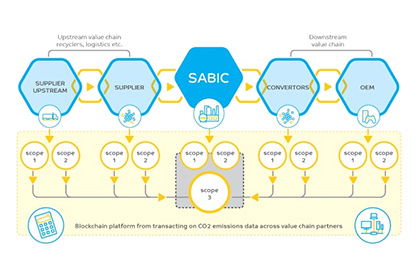

Generating and reporting Scope 3 emissions is notably complex and confronted by challenges with availability of reliable data. Accurate data on a company’s carbon footprint requires collaboration and data sharing across multiple value chain partners. Blockchain technology has emerged as a potentially efficient solution to improve the process that can bolster transparency and accountability while minimizing risk across supply chains.

SABIC’s project will employ Circularise’s technology to capture emissions across the value chain by deploying a consistent methodological and reporting framework accepted by the industry. Scope 1 and Scope 2 data captured at the material level can be used to generate Scope 3 CO2 emissions for the full value chain of targeted industries. In addition to increased transparency, the use of Circularise’s Smart Questioning technology will benefit SABIC’s entire value chain by reducing the administrative efforts associated with the data collection and providing access to upstream and downstream data provided by value chain participants, from recyclers to converters to original equipment manufacturers, among others.

“This blockchain pilot project reaffirms SABIC’s dedication to accelerating the sustainable transformation of our industry through strategic partnerships and innovative new technologies,” said Waleed Al-Shalfan, Vice President of Polymers Technology & Innovation at SABIC. “Accurately mapping emissions, especially Scope 3 emissions, will allow SABIC and others to identify and minimize hot spots along the value chain, a critical tool in our pathways to decarbonization. We encourage other upstream and downstream partners to join and consider how this technology can unlock sustainable growth at every level moving forward.”

“We're proud to collaborate with SABIC in tackling the pivotal challenges of Scope 1, 2, and 3 emissions accounting, which encompass issues like information accessibility, confidentiality, and scalability of data sharing among suppliers,” said Mesbah Sabur, Founder of Circularise. “As part of this project, Circularise aims to pilot blockchain-powered digital product passports and help businesses to track product emissions on a large scale and over time, generating comprehensive product life cycle emission reports."

This project marks another way in which SABIC is leveraging innovative partnerships to reduce emissions and help meet its commitment of becoming carbon neutral by 2050. Earlier this year, SABIC joined Together for Sustainability (TfS), a procurement-driven initiative created by chemical companies with the goal of assessing, auditing, and improving sustainability practices within their supply chains. As a member of TfS, SABIC will foster collaboration around increasing transparency in upstream value chains to support further reductions in Scope 3 greenhouse emissions.

This collaboration with Circularise also marks SABIC’s second blockchain application project. Last year, SABIC launched a pilot project with Finboot, Plastic Energy, and Intraplás to evaluate the use of blockchain technology in supporting end-to-end digital traceability of circular feedstock in customer products.