#ITMA Asia + CITME 2024

Convincing presentation, intensive discussions, agreed projects

Given the difficult situation in the global textile industry, ITMA ASIA + CITME 2024 in Shanghai was a trade fair full of expectations for many international companies, including the KARL MAYER GROUP. The leading manufacturer of textile machinery focused its exhibition on the changes and transformations in its customers' business. Under the motto “Master the Change”, it showcased solutions from all its business areas that can be used to exploit the opportunities arising from the challenges of our time. Ulrike Schlenker, my TEXTEIL NEWS editor, spoke to Kong Zhen, General Manager of KARL MAYER (CHINA), to find out how the diverse presentation was received by visitors.

US: Let's take a look at the statistics first. What do you have to say about the number of visitors? Which countries did the guests mainly come from?

KZ: We are generally satisfied with the number of guests. At our stand in the Shanghai National Exhibition and Convention Center, we welcomed over 800 visitors with specific inquiries, significantly more than at the trade fairs that took place during the coronavirus pandemic. As expected, most guests came from China. A considerable number also came from India and Turkey.

US: In your opinion, what were the crowd pullers at the KARL MAYER GROUP stand and why? What was convincing about the exhibits?

KZ: We are an innovation leader in the global textile machinery industry. Our visitors therefore always come with great expectations, which we were able to meet at this year's trade fair with a diverse exhibition program featuring the latest developments in textile machinery, textile products and their applications, digital solutions and services. The complete package with a strong market focus was very well received. The guests received a lot of valuable information and impulses for more successful production and the development of new business. One of the top exhibits was certainly the sun protection clothing presented. The comfortable outdoor outfits were made from a tricot fabric from an HKS 2-S in the new fineness E44, which impressed with its performance. Thanks to its high fineness and sophisticated design, the silky fabric offers an unrivalled UV protection factor, an extremely soft feel and a low weight per unit area.

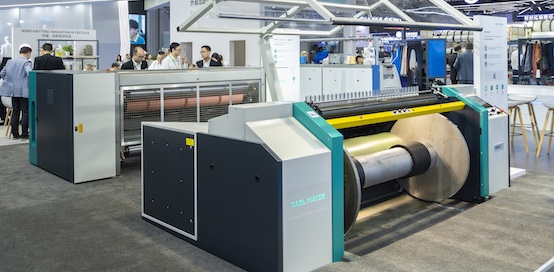

The CMS 503 ki L in E18 was a real highlight for the guests from the flat knitting industry with its unique productivity and unlimited pattern variety for a wide range of full-fashion applications. The reliable flat knitting machine with its fine gauge produced a ladies' scarf with a filigree lace-like design that impressed visitors at the trade fair. Among the digital solutions from KM.ON, the design software CREATE DESIGN and the programming software CREATE PLUS were particularly impressive with their ability to speed up the design and development process for flat knitwear. The manufacturers from the warp preparation sector could not get past our new WARPDIRECT. The latest generation warping machine scores with an extremely high warping speed and quality with the shortest amortization time. In addition, the beams produced are of the highest quality.

US: There were certainly many discussions about all these innovations. How would you rate the overall quality of the exchange at your stand?

KZ: We are even more satisfied with the intensity and content of the discussions during ITMA ASIA + CITME than with the quantity. We had in-depth professional discussions with many leading companies from different application areas and markets. The insights we gained from these show us a clear direction for our further research and development work. In addition, we were able to sign several important contracts in the course of the trade fair, which not only concern the traditional machine business, but also some new developments. We are sensing a slow return of confidence in the market, particularly as a result of a package of subsidy programs published at the end of September. We hope that this confidence will last.

US: Are we sticking to the suggestions from the discussions for further developments? What is the general direction of the journey in your business areas?

KZ: The global textile industry is and will remain dynamic and unpredictable with its ups and downs, but we are on the right track. This was shown once again at this year's ITMA ASIA + CITME. We proved that, together with our customers, we can rise to the most diverse challenges and master them with innovative technology, high-performance machines and comprehensive support. We will continue on this course. No matter how the market grows, how tough the competition is, how much the order situation fluctuates, we will continue to focus on just one thing: developing solutions that enable our customers to operate flexibly, sustainably and profitably and master the changes of our time.

US: Thank you for the interesting conversation.