#ITMA Asia + CITME 2024

Machines with a focus on the Asian market and textile developments with market potential - this is what STOLL is showing at ITMA ASIA + CITME

Guaranteed success in the flat knitting industry

“Firstly, we are seeing a growing demand for finer fabrics. We are therefore presenting a CMS 530 in the new gauge E20 for the production of fine, high-quality flat knitwear at our in-house show at KARL MAYER (CHINA) accompanying the trade fair. Secondly, we expect even faster market growth for ready-made knitwear and garments in the coming years and thus for our successful knit and wear® technology. This solution allows parts to be knitted, shaped and joined into garments almost ready to wear on just one machine,” explains Michael Händel, Vice President Sales & Service at the KARL MAYER STOLL Textilmaschinenfabrik GmbH.

Another highlight for ITMA guests will be the multifunctional ADF 530-32 ki FLEX, which will be presented outside Europe for the first time.

There will also be a textile innovation show both at ITMA ASIA + CITME and at the in-house show, with the presentation of the new STOLL trend collection NOCTURNO as a highlight. The stylish flat knitwear and fashion items inspire new products and applications and represent the diverse design potential of STOLL flat knitting machines.

Machine highlights at ITMA ASIA + CITME

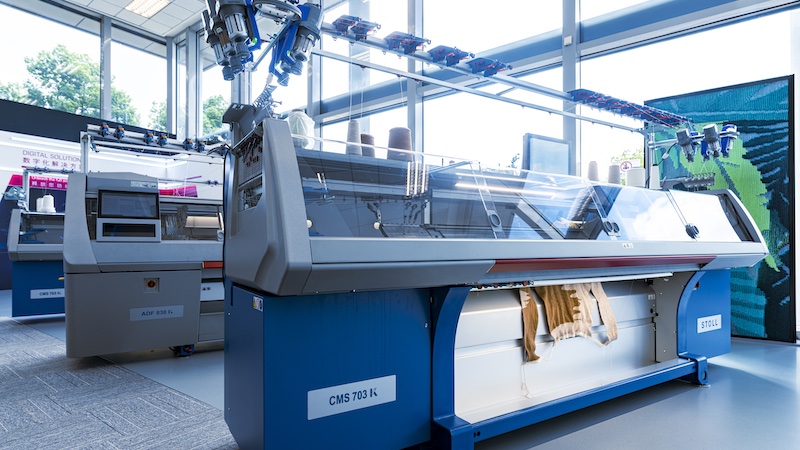

At the ITMA ASIA + CITME in Shanghai, the ADF 530-32 ki FLEX E7.2 and two new representatives of the cost-effective CMS series will be presented.

The ADF 530-32 ki FLEX E7.2 is the all-rounder in STOLL's ADF range. The universal flex machine produces all types of flat knitwear, working with completely different knitting techniques and technologies and demonstrating that STOLL is an important driver for market-driven applications and technologies. The basis for the unique performance is above all the innovative, automatic needle bed gap adjustment. The all-rounder opens up new scope for incorporating different strength ranges into garments, for example to create cuffs. In combination with STOLL-knitrobotic®, new potential can also be tapped in terms of extended integrative production processes and product design.

Under the motto “Quality meets excellent price-performance ratio”, the CMS 503 ki L and CMS 703 ki knit and wear provide answers to the challenges of the Asian market.

With a working width of 50”, the CMS 503 ki L offers unique productivity and an unlimited variety of patterns for a wide range of full-fashion applications. In addition, articles in larger sizes can also be produced - a particular advantage for international brands that need to react flexibly to a growing variety of sizes.

The CMS 703 ki knit and wear is efficient, attractively priced and unrivaled in flexibility. The production repertoire includes finished articles as well as full-fashion products. In Shanghai, a CMS 703 ki in gauge E10.2 will produce exceptionally fine and high-quality knit and wear® products with impressive productivity. Thanks to a technical extension, the machine can also work extremely reliable gores, transfer structures and bind-offs. With a working width of 72?/183 cm, the machine ideally covers the common size range of consumers, particularly in Asia.

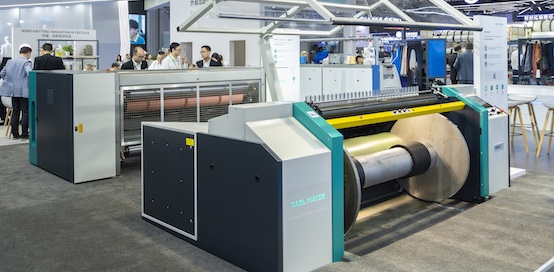

In-house show with official opening

At the in-house show at KARL MAYER (CHINA), the entire range of STOLL machines for different customer requirements will be presented. Among others, a CMS 530 in the new gauge E20 for the production of fine, high-quality articles, an ADF 830 ki E18 and a CMS 503 ki E18 will be on display. A CMS 703 ki knit and wear, here in E9.2, and a CMS 503 ki L E3.5.2 will also be available for visitors in Changzhou. The machines are part of the equipment of the new showroom at KARL MAYER (CHINA), which will be opened on the first day of the event, October 13. The heart of the innovation center is the STOLL TexLab, which invites visitors to experiment, develop products, try out technology and network.

Michael Händel is looking forward to welcoming a large audience. “Our in-house show in Changzhou, which is taking place at the same time as ITMA ASIA, will help our customers to get a detailed picture of the production possibilities and potential of modern flat knitting machines for their business.”