#ITMA Asia + CITME 2020

SHIMA SEIKI will present its vision of the future at ITMA Asia + CITME 2020

Through its exhibit theme—Step Beyond—SHIMA SEIKI will present its vision of the future, while addressing a variety of solutions for the new normal, including proposals in Factory Automation, Digital Transformation (DX), and various online solutions.

Factory automation has become a buzz word in the textile industry, the interest for which has accelerated due to the COVID-19 pandemic. At ITMA Asia we will be making proposals for factory automation centered around the special manufacturing capabilities of our WHOLEGARMENT® knitting machines. WHOLEGARMENT® knitwear can be knit in one entire piece without the need for linking or sewing, and allows for on-demand knitting. As pioneer of complete gar- ment technology with over 2,700 patents and over 25 years of experience in the field, SHIMA SEIKI will present its WHOLEGARMENT® knitting technology in the form of two of the latest machines. The flagship MACH2XS is the most advanced flat knitting machine in the world, featuring proprietary four-needle bed and SlideneedleTM technology com- bined with spring-type moveable sinkers and i-DSCS+DTC® Digital Stitch Control System with Intelligence and Dynamic Tension Control, and capable of all-needle knitting of WHOLEGARMENT® items. MACH2XS is presented in ultrafine 18L gauge, shown for the first time in China. Also shown for the first time in China, MACH2VS is a flexible V-bed machine capable of knitting WHOLEGARMENT® knitwear using every other needle, or conventional shaped knitting using all nee- dles. It also features spring-type moveable sinkers and i-DSCS+DTC® Digital Stitch Control System with Intelligence and Dynamic Tension Control. MACH2VS is presented in ultrafine 18G with auto yarn carriers as a prototype option.

The large number of patents for WHOLEGARMENT® technology is not limited to mechanical hardware, but span the range of software and programming, as well as stitch structures and knitting techniques. A variety of WHOLEGARMENT® knitwear samples featuring these patents are presented at the SHIMA SEIKI booth as well.

ITMA Asia will also be the occasion for a sneak preview of next-Generation 4-bed WHOLEGARMENT® knitting technology. Considering the recent increase in interest for WHOLEGARMENT® as a manufacturing method suited to the new normal, competing companies are slowly making their debut in complete garment knitting. This next generation in WHOLEGARMENT® technology ensures that SHIMA SEIKI remains many a Step Beyond the competition in the technology it originally pioneered. next-generation WHOLEGARMENT® technology also prepares SHIMA SEIKI for when the industry eventually takes a Step Beyond conventional knitting to adopt zero-waste sustainable WHOLEGARMENT® knitting as the next standard for knit fashion. The new machine is named SWG-XR, adopting the SWG moniker from the first-genera- tion WHOLEGARMENT® knitting machine introduced back in 1995. The "X" represents 4 needle beds arranged in an X- shaped formation as per the original SWG-X machine, while "R" stands for Reborn and Revolution, referring to a renewal of SHIMA SEIKI's WHOLEGARMENT® knitting that raises the technology to unprecedented levels. By increasing the number of systems from 3 to 4 and featuring auto yarn carriers, SWG-XR allows even higher productivity and vastly improved range of knitting for producing brand new WHOLEGARMENT® items not possible before.

In order to further support efforts in DX in the fashion industry, SHIMA SEIKI has released three new online services over the past year which will also be showcased at ITMA Asia: 'APEXFiz™' subscription-based design software; 'yarn-bank™' digital yarn sourcing web service; and 'SHIMANAVI™' e-learning service.

APEXFiz™ is the latest addition to SHIMA SEIKI's proven SDS®-onE APEX series design system lineup, but with a big departure from the past. Whereas previous APEX-series design systems were offered as an all-in-one hardware/soft- ware package, for the first time in its nearly 40 years of design system development, SHIMA SEIKI has released its new APEXFiz™ as subscription-based design software that can be installed on customers' individual computers. Maintaining proven functions that have made the APEX series so popular with fashion designers, with APEXFiz™ those strengths are now enhanced with the added versatility to adapt to different work styles and business environments including tele- working and telecommuting. APEXFiz™ software supports the creative side of fashion from planning and design to colorway evaluation, realistic fabric simulation and 3D virtual sampling.

Virtual samples are a digitized version of sample making that are accurate enough to be used effectively as prototypes, replacing physical sampling and consequently reducing time, cost and material that otherwise go to waste. APEXFiz™ thereby helps to realize sustainability and digitally transform the fashion supply chain. APEXFiz™ is furthermore available in 5 different product variations that can be selected according to the customer's needs, from APEXFiz™ Design Jr. to APEXFiz™ Design Pro.

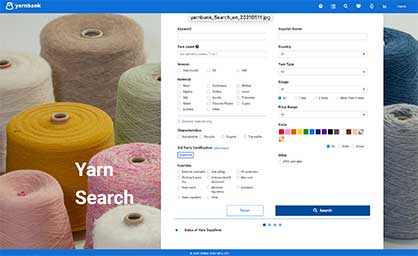

APEXFiz™ is supported by two other web services to enhance its user experience. yarnbank™ is the world's first online web service for searching and viewing the latest yarns, developed in cooperation with yarn companies from around the world. Registered users can download yarn data for free, for use in fabric simulation and virtual sampling on APEXFiz™, avoiding the need to scan yarn on their own. By using yarn that is used in actual production, designers and apparel companies can rest easy knowing that the simulations created using yarn from yarnbank™ are accurate representa- tions of what will actually be produced. With yarnbank™, the entire supply chain from yarn companies and apparel companies to knit manufacturers can be connected digitally.

Lastly, SHIMANAVI™ e-learning service allows APEXFiz™ users to experience online training when and where it is convenient, and at their own pace, supporting new work styles. SHIMANAVI™ features several courses available in different languages to suit the needs of individual customers.

SHIMA SEIKI will exhibit in Hall 4, Booth D05. Held in the midst of the CoVID-19 coronavirus worldwide pandemic, ITMA Asia is sure to be scaled down in terms of number of exhibitors, exhibition area as well as number of visitors and the number of countries from which they will be visiting. In fact, due to travel restrictions it is assumed that most interna- tional clientele will be unable to attend the show. Therefore we have prepared an online Booth where visitors can check our exhibits via the Internet, at the following URL: https://www.shimaseiki.com/itmaasia2020/

Exhibition Details

Exhibition: ITMA Asia + CITME 2020

Date: Saturday, 12th - Wednesday, 16th June, 2021

Hours: 9:00AM - 5:00PM (Final day: - 4:00PM)

Location: national Exhibition and Convention Center (nECC)

no. 168 East Yinggang Road, Shanghai, CHInA

Tel: +86-21-67008631

organizer: ITMA Services Pte. Ltd.

Tel: +65-68499368

Booth no.: Hall 4, Booth D05

online Booth: https://www.shimaseiki.com/itmaasia2020/

Exhibited Technology

MACH2XS153 18L WHOLEGARMENT® knitting machine

MACH2VS183 18G WHOLEGARMENT® knitting machine

APEXFiz™ Subscription-based design software

yarnbank™ Digital yarn sourcing web service

SHIMANAVI™ e-learning service

WHOLEGARMENT® and other knitwear samples