#ITMA Asia + CITME 2020

Picanol to exhibit at Itma Asia + CITME

Two brand new Picanol rapier machines will be premiered!

“Everyone at Picanol is eager to help our customers by providing the best technologies available on the market for airjet and rapier machines, as well as an outstanding local service and support team. The four development principles of Picanol - Smart Performance, Sustainability Inside, Driven by Data, and Intuitive Control - guide us in all our ventures. Inspired by these four principles, our R&D team has been developing some really exciting innovations that will be displayed at ITMA ASIA + CITME. These include two airjet weaving machines, four rapier weaving machines for flat fabrics, as well as one rapier machine for weaving terry towel. Furthermore, there will be an additional rapier machine in jacquard execution at the Bonas booth,” comments Johan Verstraete, Vice President Weaving Machines.

In addition to displaying the many innovations made to its range of both airjet and rapier machines, Picanol will also be premiering two new rapier machines: the brand new GTMax-i 3.0S will be shown in a 4 color dobby execution, weaving a denim style, whereas the new GTMax-S on display will be an 8 color dobby machine in 380 cm reed width weaving a silk fabric.

Picanol will also be demonstrating an OptiMax-i gripper machine in free flight execution of 540 cm width at the exhibition. This represents a significant innovation breakthrough for specific technical segments.

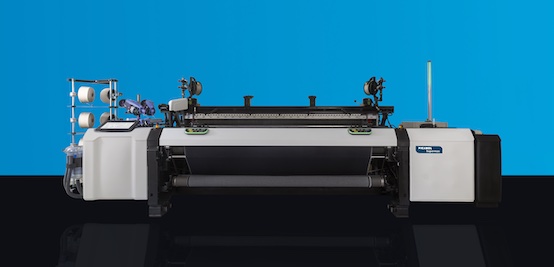

1. GTMax-i-3.0S 4-R-230 Denim

The new GTMax-i 3.0S sets the benchmark for competitive and qualitative weaving – and it’s also available in 240 and 250 cm reed width for ultimate stretch fabrics.

Warp:

• Co Ne 16/1

• Density 35.7 ends/cm

• Drawing in width 223 cm

Weft:

• PES/EL 150/40 den + PES 300 den

• Density 35.4 picks/cm

Features:

• BlueBox electronic platform

• SUMO Drive concept

• Dobby S2678B with Stäubli undermotion

• DRC2 Harness Frame connection

• Guided Gripper (GOH)

• Electronic Selvedge System (ELSY)

• Oil cooler

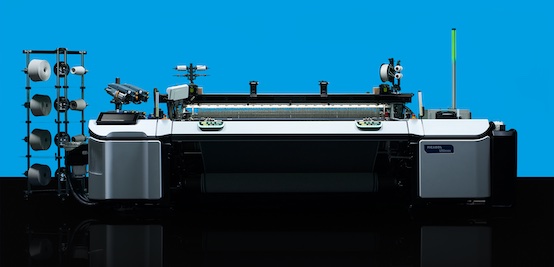

2. GTMax-S-8-R-380 Silk

The new GTMax-S with its dedicated silk execution offers you the perfect solution for weaving top-quality fabrics.

Warp:

• Silk 1/40/44 den

• Density 120 ends/cm

• Drawing in width 375 cm

Weft:

• Silk 2/20/22 den

• Density 49 picks/cm

Features:

• BlueBox electronic platform

• SUMO Drive concept

• Dobby S2658B with Stäubli undermotion

• Take-up silk execution

• Dedicated widths

• Electronic Selvedge System (ELSY)

• Center Electronic cutter

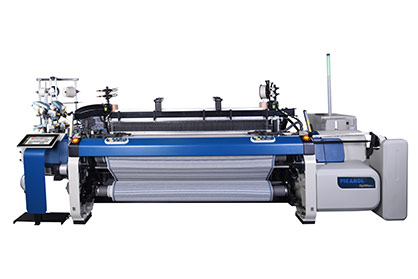

3. OptiMax-i-4-R-220 Worsted

A machine driven by data and focusing on sustainability inside.

Warp:

• Wo/PES Nm 38/1

• Density 31.5 ends/cm

• Drawing in width 188 cm

Weft:

• Wo/PA/EL Nm 42/1

• Density 27 picks/cm

Features:

• BlueTouch 15.6” display

• EcoFill 4c wasteless system

• Electronic Right Gripper Opener (ERGO)

• SmartEye filling detector

• Free Flight with carriers (VD)

• Quick Style Change (QSC)

• Smart signal lights

4. OmniPlus-i-4-P-190 Poplin

A proof that even light fabric segment can benefit from the OmniPlus-i platform. Digitization, maximum flexibility and running the highest speed.

Warp:

• Co Ne 120/2

• Density 51.2 ends/cm

• Drawing in width 170 cm

Weft:

• Co Ne 120/2

• Density 33.5 picks/cm

Features:

• BlueTouch 15.6” display

• Blue prewinders

• PosiJet main nozzle with automatic positioning

• PRA II Plus automatic pick removal and repair system

• Smart signal lights

• Quick Style Change (QSC)

5. TerryMax-i-8-R-260 Terry towel

The benchmark for terry weaving. No limitations in design, aiming at maximum performance in combination with ultimate quality.

Warp:

• Ground: Co Ne 24/2 - Pile: Co Ne 20/2

• Density 23 ends/cm

• Drawing in width 253 cm

Weft:

• Co Ne 14/1 + Chenille Nm 4 + PES 167 dtex + PP 300 den

• Density 20-144 picks/cm

Features:

• Pneumatic Pile Backrest

• Pile formation system

• Pile Monitoring

• BlueTouch 15.6” display

• Needle Roll Control

• Guided Gripper (GCv)

• Smart signal lights

6. OmniPlus-i-6-D-220 Ladies wear

Airjet equipped with a SmartShed. This is Picanol’s direct driven shedding motion and combines the best of different worlds: performance, flexibility & energy effectiveness.

Warp:

• PES 50 den + 100 den + 150 den

• Density 54 ends/cm

• Drawing in width 208 cm

Weft:

• PES/EL 150/40 den + 100/40 den + PES/CV/EL Ne 30/40 den

• Density 29 picks/cm

Features:

• SmartShed direct driven digital shedding motion

• BlueTouch 15.6” display

• Blue prewinders

• ARVD II Plus automated air saving system

• Smart signal lights

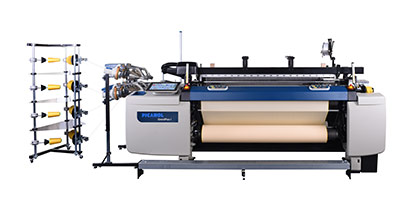

7. OptiMax-i-4-R-540 Coating

A new milestone in weaving coating fabrics. Free Flight gripper-system extended till 540 cm at highest insertion rates. No guide-hooks required anymore on widths above 360 cm!

Warp:

• PES 1100 dtex T0

• Density 7 ends/cm

• Drawing in width 520 cm

Weft:

• PES 1100 dtex T0

• Density 7 picks/cm

Features:

• Free Flight with raceboard (VB)

• Electronic Right Gripper Opener (ERGO)

• Direct Warp Control (DWC)

• Hybrid Harness Frames

• BlueTouch 15.6” display

• Smart signal lights

• Laserstop

8. GTMax-i-3.0S 8-J-340 (Bonas – Hall 3 – Booth D01)

Warp:

• PES 75 den

• Density 118 ends/cm

• Drawing in width 308 cm

Weft:

• PES 150 den + 100 den

• Density 120 picks/cm