#ITMA Asia + CITME 2018

Trützschler at ITMA ASIA 2018

Highlights on the stand:

TD 10 The new Trützschler autoleveller draw frame

ITMA ASIA marks the launch of the new Draw Frame TD 10. It features increased compactness and has a highly modern regulating system. This results in a significant increase in control dynamics and an improvement in sliver quality.

Despite 20% less space requirement, it was possible to increase the filter once more.

The intelligent SMART CREEL in combination with T-LED offers an unprecedented level of functional reliability and more comfort for the operator and mill manager.

Digitalization and connectivity are not only catchwords at Trützschler: Machines connected to T-Data allow a real-time quality monitoring.

TC 15 Benchmark in productivity

A whole range of individual measures ensure performance increases compared to the predecessor machine. In addition to high productivity, the 1.28 m wide Card TC 15 stands for increased sliver evenness and improved running behaviour. Trützschler will demonstrate the high flexibility with five different sliver coiling systems on the stand.

TC 10 The most successful card in China

Made in China – for China. The Card TC 10 is the card for the Chinese market. This Trützschler card in the traditional working width of one metre has been specifically designed for the Chinese market.

T-MOVE Space saving and increased efficiency

The can filling station does more than just save space. The new moving head allows a can change at high delivery speeds. This improves card efficiency. T-MOVE is also designed for JUMBO CANS with 1,200 mm diameter.

T-SCAN Five technologies work hand in hand for highest separation rates

In the Foreign Part Separator T-SCAN TS-T5, five detection technologies ensure an all-time high separation efficiency:

F-module - Detection of coloured parts

G-module - Detection of shiny parts

P-module - Detection of transparent and semi-transparent parts

UV-module - Detection of fluorescent parts

LED-module - Detection of smallest thread-shaped parts

IDF-Vortex - Shortened preparation system for air-jet yarns

In cooperation with the Japanese company Murata, the leading manufacturer of air-jet spinning machines, Trützschler has developed a new sliver preparation technology. When processing viscose, two of three draw frame passages can be eliminated. This represents an enormous economic advantage.

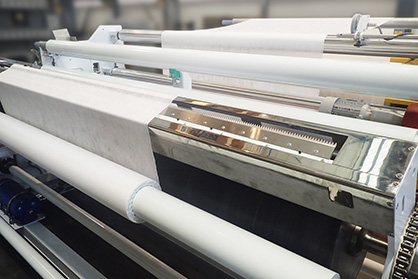

T-WIND Semi-automatic Surface Winder TWW-SD

Robust master roll winders are used when the production of ready-for-sale rolls is decoupled from the nonwovens production. The two-stage configuration with downstream unwinding, slitting and winding increases process stability. The Surface Winder TWW-SD provides an appropriate solution for spunlace systems, for a variety of thermal bonding processes as well as for technical nonwovens. Winding of master rolls up to 1,800 mm diameter and system speeds up to 300 m/min can be realised.

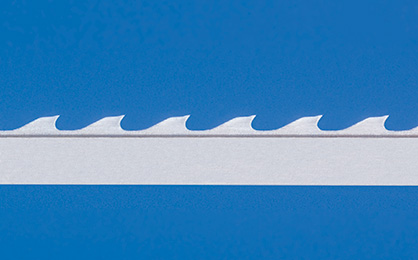

GX1 The cylinder clothing that no longer requires grinding

The new GX1 clothing has been specifically developed for all spinning processes in the area of cotton. Improved fibre guidance results in less short fibre content and significantly better nep separation. The clothing is basically maintenance-free, but can also be ground when required.

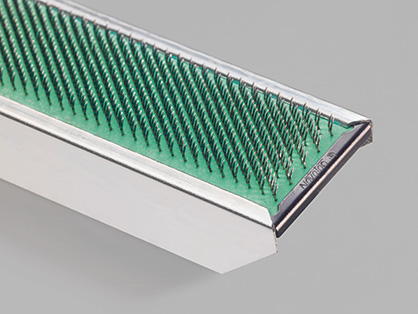

NOVOTOP 30 The very special flat clothing

The flat clothing NOVOTOP 30 has been newly developed for the processing of coarse and/or dyed fibers and reclaimed fibers for rotor spinning.

It is ideally suited for use with yarn counts below Ne 10 and realises high production speeds. The flat type NT 30 is available as MAGNOTOP and CLASSICTOP.