#ITMA 2019

ITMA 2019 - Zagis is Saurer's first customer for the newly launched air-spinning machine Autoairo

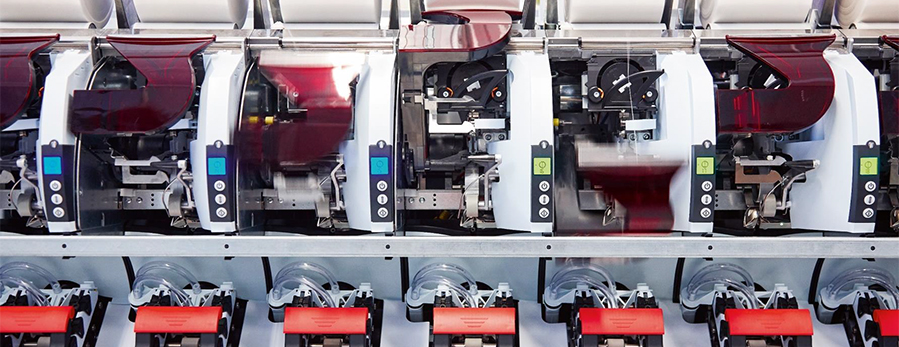

The Autoairo air-spinning machine, which the innovation pioneer Saurer launched at ITMA 2019, is a sensation, because it defines new benchmarks in productivity, efficiency and especially automation in the lucrative air-spinning market. The interest from visitors and the spinning industry in general has been overwhelming.

The Autoairo has autonomous spinning positions with individual drives, integrated intelligence and a digital piecing unit. Twenty-four piecing operations can be carried out simultaneously with SynchroPiecing 24. Compared to other machines on the market, the piecing capacity of the Autoairo is roughly twice as high. The Autoairo requires 40% less space than air-spinning machines with a one-sided design. This means that spinning mills' floor area can be smaller, which reduces construction and air conditioning costs. In this way, the return on investment is accelerated. With MultiLot, up to four lots can be spun on the Autoairo at the same time. In addition, seamless lot changes during ongoing production are possible. With PilotSpin, test packages can be manufactured while the other spinning positions simply continue with normal production. LED strips at each spinning position signal, among other things, that cans need to be replaced soon. This ensures rapid intervention by personnel without the need for cumbersome tours of inspection.

Already on Thursday, on the first day of the exhibition, we sold several Autoairo machines, the first one to Zagis, an innovative Mexican textile company, known for its use of cutting-edge technology. "The Autoairo combines the advantages of air spinning with the world's most advanced automation technologies," :I]says Mayer Zaga Galante, CEO of Zagis. "Saurer's digitised single spinning position technology is a groundbreaking basis for intelligent automation. The Autoairo is highly competitive in every respect." :I]