#ITMA 2019

Mayer & Cie. presents most productive mattress machine in the market

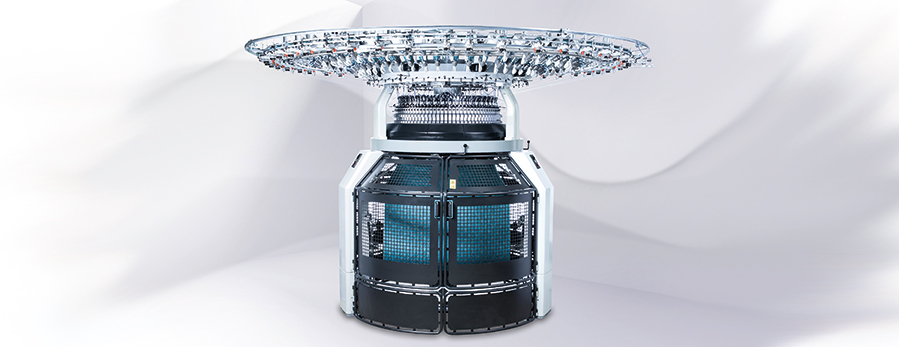

Achieve peak performance with the OVJA 2.4 EM

The star among mattress machines: the OVJA 2.4 EM

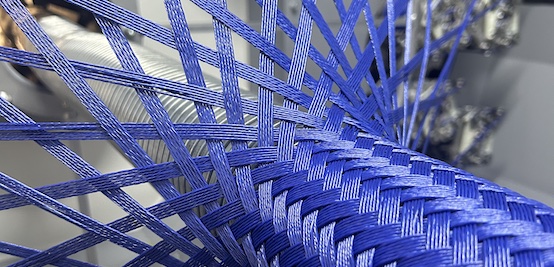

The OVJA 2.4 EM is a new Mayer & Cie. development that is specially geared to recent changing requirements in the manufacture of mattress cover fabrics. Its focus is on maximising output, which it achieves by means of a combination of a larger number of knitting systems and a higher rotation speed. “With a system density of 2.4 the OVJA 2.4 EM tallies precisely with the current trend toward higher system densities that make higher productivity possible,” explains Thomas Zizmann, area sales manager at Mayer & Cie. “The OVJA 2.4 E,” he says, “produces up to 30 kilograms of fabric per hour. That makes it demonstrably the most productive machine of its kind in the world, as shown by its speed factor of 950.” In addition to high productivity the OVJA 2.4 EM’s impressive features include ease of use and a wide range of patterns. The horizontal weft yarn guide on each cylinder segment ensures even, easy operation, short changeover times and a high level of reliability. Thanks to the improved thread guide and the air-controlled thread fluctuation control system the thread tension remains constant even at high speeds. That keeps thread vibration to a minimum and the thread is transported safely to the needles. Despite the high productivity the especially gentle needle guidance ensures an unusually low level of needle wear and tear. At the same time the OVJA 2.4 EM offers a wide range of designs that can be changed very quickly thanks to electronic single needle selection in the cylinder.

Pioneering work by Mayer & Cie.: Circular knitting captures the mattress market

Until the late 1990s all mattress cover fabrics were woven. When Mayer & Cie. developed the first electronic machine with a 38-inch diameter and an E 20 gauge in 1997, circular-knitted fabrics began to capture the mattress cover market. In just 20 years the share of circular-knitted fabrics in this segment has risen from zero to over 50 per cent and Mayer & Cie. has become the leading manufacturer. That is mainly because circular knits, in contrast to woven fabrics, are much more stretchable and flexible. That makes them easier to handle and their elasticity enables them to adapt much better to the contours of the mattress, which in turn makes them ideally suitable for flexible, spot-elastic mattresses.

The most important markets for Mayer & Cie. in this segment are Belgium and the USA, but Mayer & Cie. machines also make mattress cover fabrics in Italy, Turkey and Asia, especially China and Indonesia. “What our customers particularly appreciate about our mattress machines is the combination of great flexibility and high productivity,” says Thomas Zizmann. “In Canada and Belgium we have customers in this segment who use only Mayer & Cie. machines.”

The trend toward circular knitting in the mattress market continues, rising slightly, but a level of saturation has been reached and competition has increased. “Sadly, there is now a trend toward less expensive covers and mattresses that are being pushed strongly in advertising,” Zizmann says, describing the current situation. “That is naturally a serious challenge for our customers, who are mainly premium manufacturers. We aim to countervail this trend by increasing the production output of our mattress machines.”

Mattress specialists: the fully electronic OVJA machines from Mayer & Cie.

For the production of high-quality mattress cover fabrics Mayer & Cie. has a range of purpose-built machines. Pattern variety, ease of use and productivity are the key factors. Mattress patterns are among the most complicated that are manufactured and the fully electronic circular knitting machines in Mayer & Cie.’s OVJA range deliver precisely these benefits.

The OVJA 1.6 E has proved its worth for many years as an extraordinarily flexible jacquard machine that is highly productive and thanks to its electronic needle selection does the topstitching in a single operation. Mayer & Cie. continued to develop the OVJA 1.6 E for making mattress covers, leading to the appearance of the OVJA 1.6 EM, a highly productive electronic jacquard machine. The OVJA 1.6 EM HS, a double-knit jacquard machine with electronic single needle selection, is ideally suited by virtue of its flexibility and productivity for the manufacture of mattress cover fabrics. The OVJA 1.6 EE comes with a further increase in numbers of patterns and structures. Electronic single needle selection in both the cylinder and the rib dial opens up many new options. The OVJA 2.4 E, also an electronic jacquard machine designed mainly for production of mattress cover fabrics, knits all known structures including relief and combines high productivity and ease of operation.

In the OVJA 2.4 EM Mayer & Cie. now presents a mattress machine that outperforms all previous machines in its segment for productivity, is decidedly user-friendly with a wide range of patterns.