#ITMA 2019

Mahlo brings latest trends to ITMA 2019

Via the „Gateway to Industry 4.0“ visitors can immerse in the digital world of Mahlo. mSmart is the name of the concept developed by the technology leader from Bavaria, that defines the digital environment. “Our systems generate data, which the client can use immediately to control on-line. In addition to that, those figures are logged in our new data management system and are retrievable at any time in order to optimize processes and minimize weak points in the production”, Sales Director Thomas Höpfl explains. How measuring data are saved, logged and evaluated, that visitors can test in the mSmart control room. The real-time data of all machines displayed come together here, so every change in a machine can be observed.

The Future of Straightening & Process Control

In the textile industry, the name Mahlo is equivalent to high-end automatic straighteners and process control systems. The experts’ recipe for success is decade-long experience paired with the latest technological developments. Exactly this combination has made Mahlo the world market leader for weft straightening. At the ITMA, the company stays true to its strategy and showcases according to the motto “The Future of Straightening and Process Control” the latest advancements. In live operation, the most recent generations of weft straightener Orthopac RVMC-15 or web gauging system Qualiscan QMS-12, why they enhance every textile production line. Patcontrol PCS-15 for pattern control and Famacont PMC-15 for controlling weft thread and mesh density also contribute to high-quality textile production and finishing. Both are also in live operation at the ITMA. People interested can have the operation principle explained with the help of a demo tower and their own or provided fabric samples at the Mahlo booth.

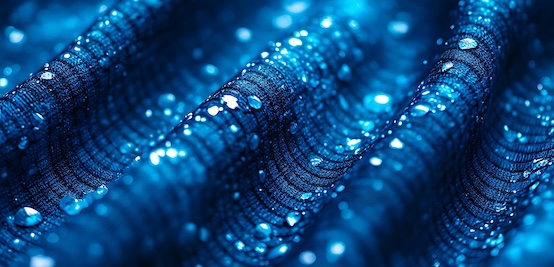

Denim-Corner

For especially heavy cases, a separate area is reserved at booth H2-C203: at the Denim-Corner everything revolves around the rugged cotton fabric. The popularity of denim is constantly rising, with no end in sight. Equally increase the end customers’ expectations on design and functionality – and therefore also on the producers. Mahlo introduces in Barcelona a new high-end-solution for straightening the demanding material. “The new technology allows exact and quick controlling even of the heaviest web. In a way unprecedented in the denim industry”, says Höpfl.

A meeting point to connect and establish new contacts will be - just like at previous ITMAs – the Mahlo Bistro. Here, visitors can enjoy Bavarian specialties and recapitulate, how they can improve their production processes.