#Weaving

Stäubli showcases advanced weaving solutions at Dhakatex 2025

Innovative Solutions for weaving mills

At Spintex’s stand, visitors will have the opportunity to explore Stäubli’s cutting-edge technologies designed to streamline warp preparation, weaving automation, and process optimization. Some of the key solutions on display include:

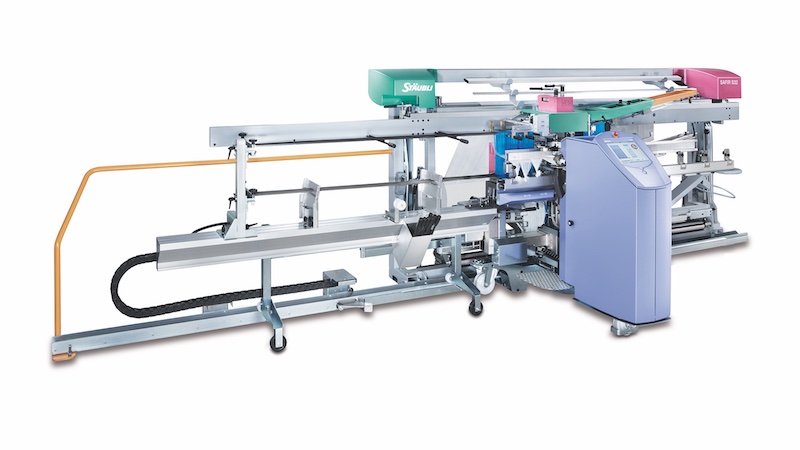

+ SAFIR S32 Automatic Drawing-in System – Accelerates warp preparation and enables quick style changes, ensuring higher productivity.

+ TIEPRO Warp Tying Machine – Adapts to a variety of warp sheets, both with and without a 1:1 lease, delivering superior flexibility and efficiency.

+ S1600/S1700 Cam Motion Series & S3000/S3200 Electronic Rotary Dobby – Engineered for high-speed weaving on air-jet, water-jet, rapier, and projectile weaving machines, ensuring seamless production with consistent quality output.

+ PRO Series Jacquard Machines with NOEMI Electronics – Optimized for energy efficiency, this innovation reduces power consumption while maintaining precise hook selection and reliability.

A commitment to modernization & sustainability

Stäubli’s participation at Dhakatex 2025 reinforces its commitment to supporting weaving mills at every stage of their operations, from process automation to energy-efficient solutions. By integrating these advanced systems, mills can achieve modernization, improved sustainability, and higher production efficiency.

Weaving professionals and industry stakeholders attending Dhakatex 2025 are invited to visit Spintex’s stand to experience these innovations firsthand and explore how Stäubli’s solutions can enhance their textile production workflows.

For more information, visit Stäubli’s representatives at the exhibition or contact Spintex for a personalized consultation.