#ITM 2022

Sedo Treepoint at ITM 2022 – Smart Factory solutions for improving sustainability and digitalization.

Sedo Treepoint is again part of the ITM exhibition in Istanbul.

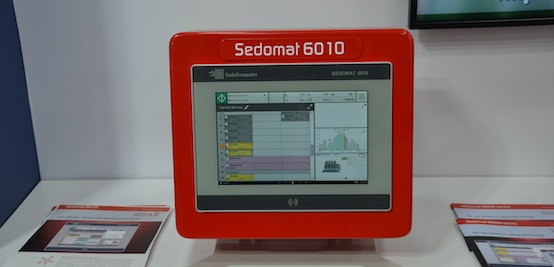

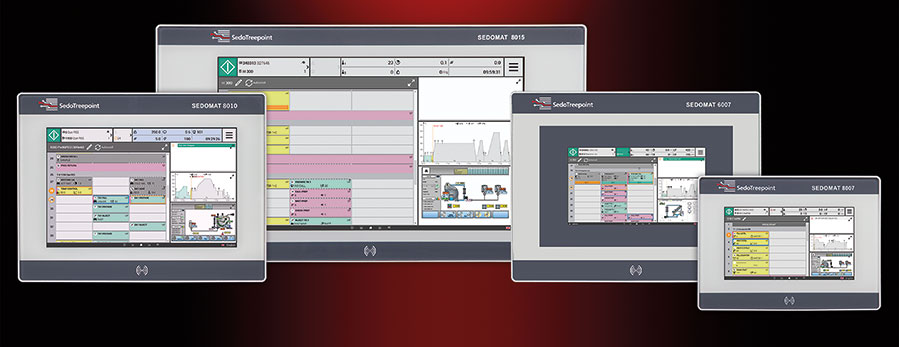

In addition to the well proven benefits of the Sedomat controllers, the new series is more flex- ible and offers different interface options like CANopen, Profibus DP and MODBUS RTU. To improve the communication between different systems, OPC UA and MQTT interfaces will enhance data communication.

SedoMaster is the core of the production shop floor: Intelligent central production planning, control, monitoring, and reporting becomes available. It is a useful tool for all key operators and the management due to the connection of all dyeing and finishing machines. Powerful reporting gives information on productivity, resource costs and OEE. SedoMaster also links all periphery systems like dispensers, dissolvers, or ERP systems.

Within the past years, energy cost becomes one of the most important cost factors for the textile finishing industry. EnergyMaster calculates the energy consumption in production and gives the required information to optimize energy use. This results in a better carbon footprint and saves a lot of cost.

ColorMaster is the most expert system for recipe management and color measurement. The Windows based software calculates the best and most cost-effective recipe in laboratory and in production it offers the best possible treatment and correct dye program selection. Colori- metric control within different production steps and calculation of additions for addition treat- ments supplement its functionality.

The Textile Manufacturing Simulation system (TMS) is developed to create the most effi- cient production schedule for all active production orders (SFOs). With TMS all orders can meet their delivery date and the machine utilization is enhanced. Further advantages are opti- mized resources and energy costs as well as improved quality.

Morapex enables reliable, non-destructive tests in some minutes. Its main functions are an- alyzation of pH value and residuals, control of wash procedure, check of wash and water as well as perspiration fastness. Testing with the systems is possible at any stage of production and in laboratory.

The perfect tool to optimize/automate wash- and rinsing process is Ecomat. It comes with optical RGB-technology and checks online the water clearness during washing/rinsing after the dyeing process. Connected to the Sedomat controller, it can automatically optimize and automate the rinsing process.

With the new SedoAPP all production data can also be displayed on mobile devices.?Using a Sedo SmartBracelet the machine operator will get every notice directly on his wrist.

He can act immediately when a machine requires his attention.

With Sedo Treepoint systems, you can get many cutting-edge features for the Smart Factory and along with smart software solutions the complete textile supply chain is integrated trough intelligent production. Sedo Treepoint products help to improve sustainability, reduce costs, and increase productivity and efficiency at the same time.