#ITM 2022

ITM 2022: Rieter further improves attractiveness of ring and compact-spinning system

• Autoconer X6 is the key machine for highest efficiency

• Roving frame F 40 sets industry standard at 90 seconds only for doffing

• New top and bottom aprons NO-79201 offer greater durability

• i-Bearing enables 24/7 visibility for fast and smart decisions

• Berkolizer pro introduces easily adjustable UV treatment as industry-first

• European roll out of precision winder NEO-YW to launch in Turkey

Autoconer X6 Is the Key Machine for Highest Efficiency

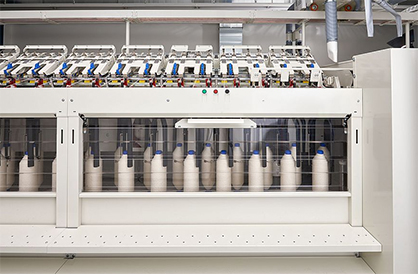

The Autoconer X6 is a globally recognized winding machine at the highest performance level, putting it on a par with all other Rieter machines. The winding machine serves as the final quality assurance in the ring and compact-spinning process and is key to the performance of the subsequent process stages.

The latest splicer generation OZ1 (Ne 20 to Ne 120 and finer) and OZ2 (Ne 3 to Ne 40) provides an optimum splice quality based on an open prism. When splicing cotton-based elastic core yarns, duo-core yarns and multi-core yarns, the open prisms are used in combination with the Elastosplicer. This has already been successfully introduced in vertically integrated mills.

The new Multilink system with Multilot offers maximum flexibility: Up to four ring spinning machines are linked to one Autoconer, with each ring spinning machine able to supply a different type of yarn.

With the integration of the Autoconer X6 into the Rieter system, the mill management system ESSENTIAL will open up over the coming years the potential for end-to-end transparency and optimization throughout all process steps.

The roving frame F 40 was already introduced to the market at ITMA 2019. A precise bobbin build-up in combination with a doffing time of 90 seconds only and the option of setting the drafting system electronically are convincing customers to invest in this machine in combination with Rieter systems.

SSM is presenting the NEO-YW precision winder which brings to bear SSM’s unmatched winding expertise into one easy-to-use and high-performing machine. NEO-YW will kick off its launch into the European market at ITM 2022.

Components for Higher Performance and Durability

The newly acquired Accotex and Temco brands are adding strength to the components family, which now includes Accotex, Bräcker, Graf, Novibra, SSM, Suessen and Temco. Rieter is presenting three key innovations at ITM.

Accotex’s new top and bottom aprons NO-79201 offer outstanding tear and abrasion resistance and superior friction properties. They can be applied universally, making service and stocking more efficient.

Temco’s intelligent bearing solution i-Bearing for filament machines allows condition monitoring online. By identifying critical conditions, bearings can be replaced before they fail which helps to minimize machine downtimes.

Today, Bräcker’s berkolizing technology of treating rubber cots with UV light to improve the surface has become an industry standard. At ITM, Bräcker is introducing the berkolizer pro which stands for consistent, energy-efficient, and adjustable UV treatment.

Opportunities and Challenges to the Spinning Industry

2021 was an unprecedented year for the global spinning industry. Driven by the market recovery after the pandemic and the regional shift of the industry, customers invested in new spinning systems at levels never experienced before. And despite the current uncertainties, customers continue to invest.

As market and technology leader, Rieter succeeded in this environment in posting a record order intake for 2021. This is clear evidence of the high level of trust customers have in Rieter. Dr. Norbert Klapper, CEO of Rieter, says: “Systems, machines, components, parts and services from Rieter have ensured competitiveness and success for customers over many years in the past and will continue to do so in the future.”

Dr. Klapper also comments on the challenges that lie ahead for the industry as it takes advantage of market opportunities: “The pandemic is not over yet, and business is exposed to dramatic cost increases as well as shortages in material supplies and logistics. In difficult times, it is important to work together even more closely than under normal circumstances. It’s all about true partnership and trust – the basis of Rieter’s business for 226 years.”

Visit Rieter at ITM 2022 at TÜYAP Fair Convention and Congress Center, Istanbul, Turkey, from June 14 to 18, 2022 in hall 3-314 at booth C07. Register to experience our virtual booth from anywhere, anytime via www.rieter.com/company/virtualworld with the ITM 2022 edition going live June 10, 2022.