#ITM 2013

Picanol at ITM Texpo Eurasia 2013

Turkey is one of the world’s key textile markets. The country earns about 5.7% of its total foreign exchange through textile export and the textile industry realizes nearly 30% of the country’s total industrial output. The Turkish textile industry is also the country’s largest industry in terms of employment – it currently employs more than 2 million people.

Picanol has been serving the Turkish textile industry for more than 50 years. In 1998, Picanol set up a Turkish subsidiary, in order to more actively support its local activities. Today Picanol is the leading provider of weaving machines in Turkey. At the ITM show, Picanol will present two of its most advanced rapier weaving machines.

Picanol Marketing Communication Manager Erwin Devloo says: “Winners are the ones who get the most out of every single opportunity, who grasp every single chance. The ones who dare to reach out and seize the moment. Those who go for growth and act fast, with a long-term future in mind. So, are you a winner? Have you got the plans, the objectives, the talent and the stamina to make you a winner? Good. Because in that case, Picanol will be there for you. Meet us at ITM!”

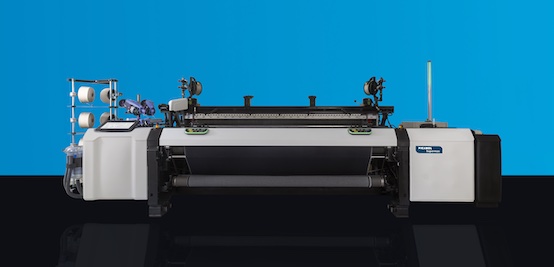

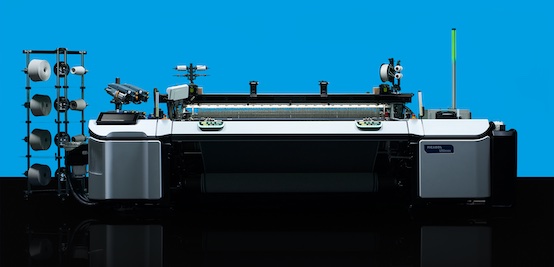

Picanol weaving machines on display at ITM Texpo Eurasia 2013

OptiMax 4-R 190 – denim Warp yarn count Ne 8.6 material cotton density 24.8 ends/cm Weft yarn count Nm 12/1 (corespun) material cotton density 19 picks/cm Drawing-in width 184 cm

A 10oz denim style with corespun filling yarn is woven on this advanced rapier weaving machine with Guided Gripper system (GC), which is the standard solution for spun yarns. The rapier tape of the light-weight GC system is perfectly guided by one-piece hooks. This weaving machine runs at industrial speeds that were never reached before.

The Electronic Disc Cutter (EDC) cuts the filling yarn always at the right moment, while clamping the filling.

The machine is executed with a split frame – ready for the Picanol Quick Style Change system. The quick harness connections, the roll-away filling creel, the hand-operated quick snap locks for warp beam and cloth rolls, and a microprocessor for modifying crossing time settings for selvedges and shed are all standard on the Picanol OptiMax looms and keep machine downtimes ultra-short.

OptiMax 8-R 340 – fancy voile Warp yarn count dtex 22/1 material polyester density 37 ends/cm Weft yarn count dtex 78 up to Nm 4 material PES, PES/CO, chenille density varies Drawing-in width 314 cm

The Free Flight system (FF) is specially designed for weaving delicate fabrics, providing maximum filling versatility and warp friendliness. The system is covered by raceboard for gentle treatment of the filament warp yarns.

The Electronic Selvedge System (ELSY) full leno selvedge motions are electrically driven by individual stepper motors. The selvedge crossing and pattern are programmed on the microprocessor independently of the shed crossing, even while the machine is in operation, so the result of a resetting can be checked immediately.

The Electronic Filling Tensioner (EFT) is a completely new active brake. By using long lamellas, the braking force is distributed over a long filling length. The combination of the long braking plates and the damping properties of the spring system allows to decrease the static tension to an absolute minimum.

With the SmartEye, Picanol launches a filling detector with extra functionalities. The SmartEye filling detector allows individual sensitivity setting per eyelet and verification of a correct channel insertion.