#Dyeing, Drying, Finishing

Building a textile technology backbone in Bangladesh

The DTG takes place at the International Convention City Bashundhara (ICCB) in Dhaka from February 20-23 and will showcase the technologies of over 1,000 textile machinery brands and suppliers from 31 countries across its nine halls.

The successful 30-year partnership between Monforts and Bengal Technology and Engineering in Bangladesh has grown in parallel to the rapid rise of the nation’s textiles and apparel sector – from just a handful of manufacturers to over 6,000 factories today – and in particular, its growth into the world’s second largest exporter of readymade garments (RMGs).

Many of the world’s leading fashion brands have chosen to establish operations in Bangladesh, drawn to the country’s efficiencies and highly integrated network of rapidly responding suppliers.

Hoping to build on this success, the Bangladesh government has now initiated plans to achieve exports of RMGs worth $50 billion by as early as this year – and approaching $100 billion by 2030.

To realise this, however, the reinforcement of a textile manufacturing backbone will become increasingly crucial, and Monforts has much to contribute to ensuring the Bangladesh industry continues to grow sustainably.

Focus on CO2 footprint

“We have always specialised in advanced technology for fabric finishing based on successive industry developments over many decades,” says Monforts Head of Denim Hans Wroblowski. “Monforts Montex stenters – for processes such as drying, stretching, heat-setting and coating – are the industry standard for the fabric finishing industry, particularly in the sectors of denim and home textiles, providing a number of advantages in terms of production throughput and especially in energy efficiency and savings. These machines remain unmatched in terms of their robustness and long service life, as well as resource-efficient productivity.

“CO2 footprint is very much our current focus, and because finishing is a particularly energy-intensive part of the textile production chain, it is exactly where convincing results can be achieved,” he adds. “We have developed a wide range of energy-saving measures and a notable innovation here is our VarioMatex padder, which can be quickly adjusted to suit the fabric being processed. Mechanically squeezing out water with a padder is much more energy efficient than thermal drying, but synthetics and natural fibres, as well as knits and wovens, require differing roll hardnesses for maximum effect. Our EcoApplicator, based on kiss-roll application, is the right choice for functional sportswear.”

For Thermex hotflue and Montex stenter solutions, Monforts has also developed a range of heat recovery and energy optimisation options enabling overall energy savings – up to 40% compared to conventional stenters. These include the Universal Energy Tower, a free-standing air/air heat exchanger that achieves energy savings of up to 25%. The ECO Booster heat recovery system with integrated automatic cleaning is meanwhile directly integrated into the chamber design of the Montex stenter and enables energy savings of up to 35% depending on the application. One ECO Booster module is sufficient for stenter ranges with up to eight chambers.

The VarioMatex, EcoApplicator, ECO Booster and Energy Tower can also be retrofitted to existing ranges without having to invest in a new machine.

“If anything, today’s high energy prices are only encouraging investment, because for our customers, energy costs can account for up to 70% of production costs, so there is great demand for ways of saving money,” Wroblowski observes. “This also helps in terms of global warming and reducing carbon footprint, of course. We see the energy crisis of the past few years as an opportunity because it is leading to an energy consumption rethink in the textile industry.”

Thermex

Over 900 Monforts Thermex hotflue dyeing systems are now operational in the main textile producing countries, including Bangladesh, with around 150 of them already reaping the benefits of the Econtrol® and Econtrol®T-CA processes. Many are specifically dedicated to the production of denim.

Econtrol® is a continuous process for the dyeing of woven cotton and cellulosic fabrics in which reactive dyestuffs are fixed into the fabric in a one-step dyeing and drying process with a controlled combination of steam and air. The entire pad-dry process takes just two-to-three minutes at a temperature of between 120-130°C and a relative humidity volume of 25-30%.

MontexCoat

The MontexCoat coating unit is one of the latest additions to the Monforts portfolio and the first of these systems in Bangladesh has recently been installed at a plant belonging to leading conglomerate DBL Group.

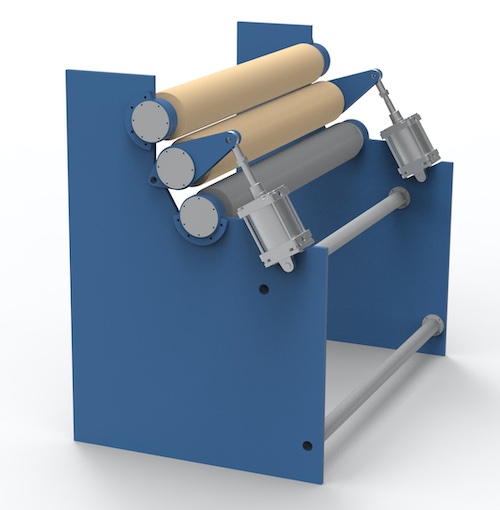

The MontexCoat can serve a very diverse number of markets and enables full PVC coatings, pigment dyeing or minimal application surface and low penetration treatments, as well as solvent coatings. Knife coating, roller coating or screen printing can also all be accommodated with this system.

As such, it provides the ultimate in flexibility and the ability to switch quickly from one fabric run to the next, without compromising on the economical use of energy or raw materials.

As a more specific coater, Monforts has recently introduced the coaTTex, which is exclusively dedicated to air knife and knife-over-roller coating. For single-sided application with paste or foam, the versatile coaTTex is suitable for both incorporation into existing finishing ranges as well as installation with new Monforts lines, notably the industry-leading Montex stenter systems.

“We are now experiencing high interest in both the MontexCoat and coaTTex units from the Bangladesh market,” Hans Wroblowski concludes. “We offer full assistance in the supply of our advanced dyeing and finishing technology, with full service support and Bengal Technology and Engineering has been the perfect partner to us in Bangladesh. Come and talk to our experts at DTG!”