#ITMA Asia + CITME 2020

BRÜCKNER – at home in Shanghai!

For more than 70 years the German textile machinery manufacturer BRÜCKNER has been the world leader in the field of dry finishing of textiles, technical textiles, nonwovens, glass fabrics and floor coverings. In-house production in Germany ensures a high level of system diversity and enables fast and flexible adaptation to customer requirements. Worldwide, about 90 agencies work for BRÜCKNER, so that customers have a local contact person in almost every country of the world. China is one of the most important markets worldwide in the textile industry, therefore two agencies have been working here for BRÜCKNER for many years. In order to be even better positioned in the future, BRÜCKNER founded its own branch office in Shanghai at the end of 2019. Besides the staff for sales, service and administration, BRÜCKNER's own technicians are on the road all over the country to commission machines and to attend to customers personally. Depending on demand, the technicians are also on the road throughout Asia. If travel times and distances allow, service calls can be realized within 24 hours. In addition, a local spare parts stock in Shanghai offers customers rapid availability of original parts.

From June 12-16, 2021, BRÜCKNER will present its product portfolio and services at ITMA ASIA in Shanghai. In hall 6, booth no. A18 the BRÜCKNER team is looking forward to its visitors! These can look forward to new features relating to Industry 4.0 and automated production. Among them is an intelligent assistance system that gives the machine operator valuable tips on setting the individual machine parameters. For example, he is shown how he can save even more energy while maintaining the same level of productivity. A newly developed maintenance manager monitors all processes in the background and supports the operating personnel in planning maintenance and cleaning work. The system also provides information on the timely reordering of wear parts. All current production data can be accessed at any time via the new dashboard tool, such as batch size, energy consumption and machine downtimes. If the support of a BRÜCKNER technician is necessary, many service cases can also be solved online via augmented reality. This also helps over distance and saves time for both sides.

Visitors of the trade fair can also inform themselves about further products and services of BRÜCKNER. For example, when it comes to coating technical textiles. BRÜCKNER has already supplied many lines in this field with fabric widths up to 7 meters. Here, both first-class machines and competent advice are essential. With BRÜCKNER you get everything from one source! In the field of knitted fabric finishing, BRÜCKNER has been the world leader for decades. No matter whether extremely sensitive fabrics such as lace or fabrics with a high elastane content are to be finished or whether knitted fabric is to be coated directly, BRÜCKNER offers for every application the perfect solution individually adapted to the customer.

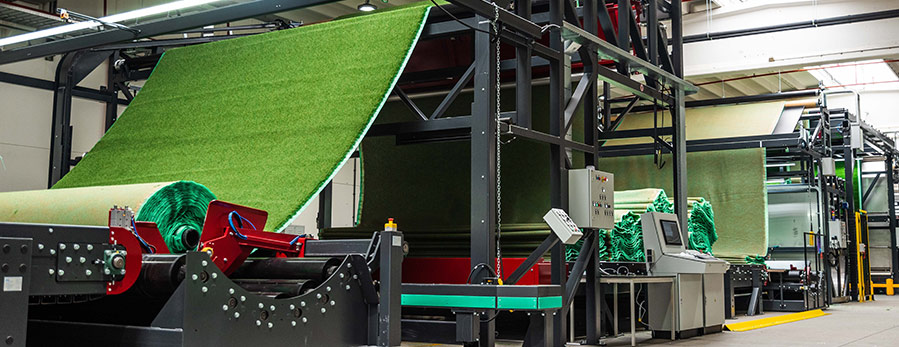

Also in the nonwovens sector BRÜCKNER has developed a lot in the last years. The different ovens in BRÜCKNER's product portfolio dry and consolidate nonwovens materials for the most different fields, such as e.g. hygiene and medical textiles, building and geotextiles, filter materials as well as fabrics for clothing, cleaning, care and vehicles. Various application systems such as foam impregnation units, coating machines, kiss-roll or flocking units complete the product range. BRÜCKNER offers complete lines for the finishing of carpets, PVC floor coverings or artificial turf. Of course BRÜCKNER offers for all lines also corresponding components for energy saving. Heat-recovery and pollution control systems are the most efficient, allowing customers to achieve significant energy savings depending on the type of fabric and process. Due to the modular design, BRÜCKNER lines are also very easy to clean. In addition to reducing the consumption of valuable resources, these lines also make a significant contribution to environmental protection. In addition, the company offers comprehensive and integral energy consulting, specifically adapted to the circumstances of each individual customer.