#Dyeing, Drying, Finishing

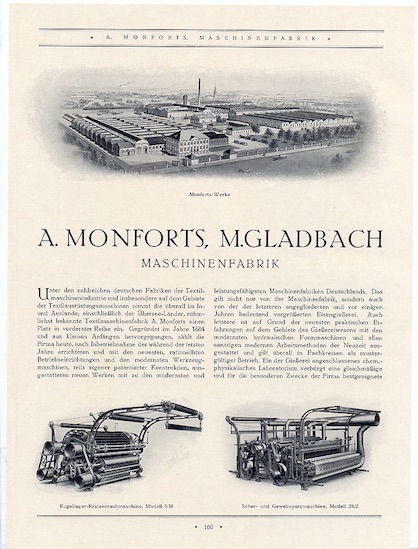

Revolutionary machine returns to Monforts after more than a century

The machine remained in operation at a plant in Poland up until early 2000 and has now been handed back in full working condition to its manufacturer.

Monforts veterans Walter Dresen and Fred Vohdahl – both of whom each worked for the company for more than 50 years and are themselves now retired – ensured the smooth landing of the machine as it was unloaded from its delivery truck.

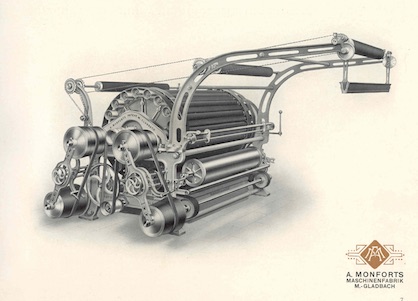

The raising machine was introduced by Monforts at the end of the 19th century and represented a gamechanger at that time, due to the use of low friction ball bearings for its raising rollers. This greatly reduced the wear and maintenance of the raising rollers and was a first for the market.

Spirit of innovation

“We are proud to have such an old-timer now on display at our ATC,” says Monforts Marketing Manager Nicole Croonenbroek. “It demonstrates the spirit of innovation that has been a part of Monforts since the company was founded in 1884 and is now in our genes.

“Our two former collleagues, Walter Dresen, our Head of Service for many years, and Fred Vohsdahl, who was the Manager of the ATC until his recent retirement, took charge of the rebuild and restoration work. They have been able to find and replace the leather transmission belts which were the crucial drive element between what would originally have been a steam engine and the raising machine in the textile mill.

“Visitors will be interested to see this example of Monforts Industry 1.0 engineering and can compare it to the latest Industry 4.0 features of our latest finishing lines at the ATC.”

Despite any current travel restrictions, the Monforts Advanced Technology Centre (ATC) is fully operational for industrial-scale trials which go beyond lab or pilot plant testing, to be run by highly experienced staff on behalf of customers.

Since its opening in 2013, over €3 million has been invested in equipment at the ATC, which over an area of 1,200 square metres, houses two full finishing lines, engineered to accommodate an extremely diverse range of processes based around the industry-leading Montex stenter, in addition to a Thermex range for continuous fabric dyeing and the newly developed CYD process for yarn dyeing.