#Dyeing, Drying, Finishing

SETEX at ITMA Barcelona 2019

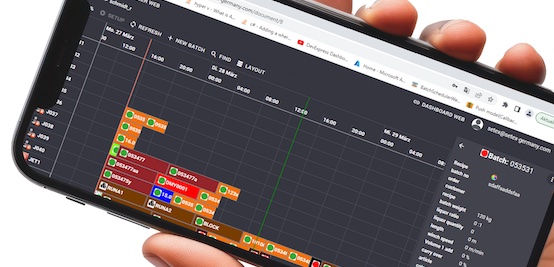

As expected, interest in the new controller E390 and C390 was high.

Their special feature apart from size and resolution: They use a swiping user interface for the top, middle and bottom of the screen, which provides the user with information and operation of the running process, without losing the overall view.

- Intelligent software wizards allow program creation by drag-n-drop of dyeing charts.

- Split screen for picture-in-picture representation of machine-specific functions and video monitoring make everyday production easier.

- Integrated OPC/UA client and server makes it easy to get an overall plant overview and advanced communication capabilities with machines and the OrgaTEX MES software.

The concept of the SETEX stand as a unit for total solutions has worked.

It's not just about products, it's about management with the possibilities of Industry 4.0.

OrgaTEX BI analyzes show the influence of a machine, a process or the production environment on the production result.

OrgaTEX Energy Management and the power of the Plant Navigator algorithms balance the resource consumption of water, steam, gas and electricity with the production machines.

Costs of machine downtime and penalties for late deliveries affect the effectiveness of production. To prevent this, the OrgaTEX Maintenance Manager calculates when the best time for maintenance is. The integrated solution with condition monitoring of the machines, visualization at the controls and criteria evaluation in the MES system ensures, that maintenance work fits into the production process in sync with the detailed planning. Integrated digital machine documentation and recommended spare parts are contributing significantly to a more efficient production.

The new OrgaTEX-inteos Manufacturing Operations Management (MOM) - sometimes referred to as production management - involves process execution along the entire textile production chain, from fiber to product and from recipe to delivery.

In response to the OEM customers, they have further developed the proven camera mount technology CamCount V3 to perform image and database analysis on a single SETEX C390 DIN rail mount controller.