#Digital Printing

Print Palace Textildruck redefines the future of custom textiles

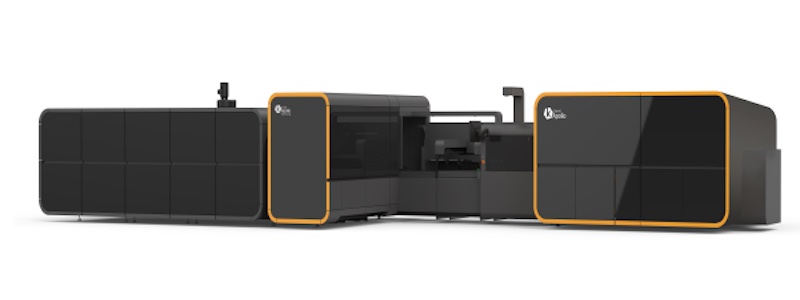

A leader for more than 30 years, Print Palace delivers some of the most robust, creative, quality apparel for top bands and fan merchandise, promotional apparel and branded fashion. Originally dedicating much of its production capacity to screen printing, the company is now making a significant digital transformation by making its first move to digital – transitioning production volumes to on-demand, digital production. Supported by Kornit’s new All-Inclusive Click (AIC) model, the producer plans to use Kornit Apollo to handle production jobs of up to 500 pieces to improve overall speed and time-to-market, and additionally make its screen-printing business more profitable through a combined production approach.

“During the past several years, we’ve seen the number of jobs of up to 500 pieces dramatically increasing, combined with the demand for high quality, color vibrancy, and unique designs. This caused major bottlenecks in our screen production,” said Volker the Owner of Print Palace Textildruck. “Kornit Apollo is one of the biggest developments we’ve seen in digital production in years and is by far an elite solution for medium-run production. Teaming with Kornit, we’re going to be able to deliver to customers what they want, when they want it – and at the level of quality and vibrancy they’ve come to expect from us.”

“For custom apparel and merchandise, customers are no longer willing to place an order and then wait weeks to receive finished goods. Apparel such as t-shirts and branded wear is all about creative self-expression, allowing the wearer to express their thoughts, feelings, and emotions - and share it with the world almost instantaneously. Screen printing was not designed to make that happen,” said Ronen Samuel, Chief Executive Officer at Kornit Digital. “With the Kornit Apollo and the new AIC Model, we’re enabling producers to directly answer this demand through high-quality on-demand production. We’re honored to team with such an industry leader as Print Palace Textildruck to help customers easily fulfill their dreams through the ultimate in custom apparel.”

The future of on-demand digital textiles is being realized today with Kornit Apollo.