#Digital Printing

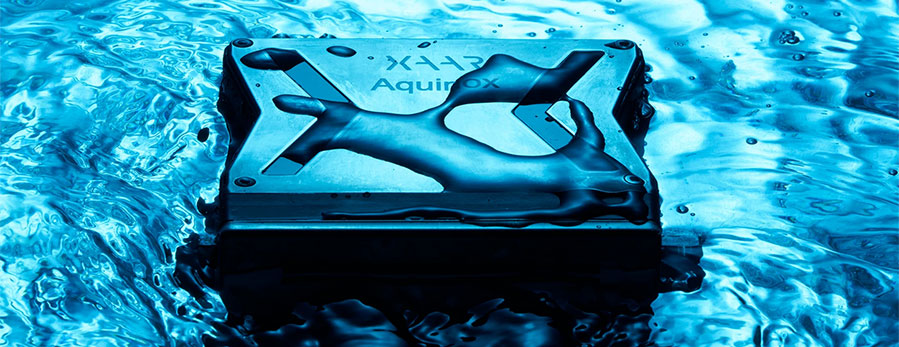

New Xaar Aquinox printhead revolutionises reliable aqueous inkjet printing

The Aquinox is the latest development from Xaar’s ImagineX platform, and its revolutionary aQ Power Technology provides a radically new approach to how water-based fluids are jetted reliably, delivering a truly transformational industrial printhead.

Xaar’s aQ Power is a combination of ground-breaking technologies designed to optimise the Aquinox’s lifespan and robustness when handling aqueous fluids. These include a redesigned internal architecture, new water compatible materials capable of coping with an extended working range of pH levels, and a revolutionary new drive system enabling optimum drop ejection. This, together with Xaar’s TF Technology ink recirculation, ensures the Aquinox delivers significantly increased nozzle open time compared to typical aqueous printheads.

Water-based inkjet printing has never been more effective or versatile thanks to the Xaar Aquinox’s unique technologies, exceptional print speeds and compatibility with multiple aqueous fluid types. Speeds of over 100m/min can be achieved, and a high native resolution of 720dpi and firing frequency of up to 48kHz, enables high fluid laydown, with maximum productivity. And with Xaar’s High Laydown Technology the drop size capability is extended, making the Aquinox ideal for printing textiles, highly absorbent substrates, or thick film coatings.

Thanks to Xaar’s Ultra High Viscosity Technology the Aquinox is capable of jetting fluid viscosities of up to 100cP. By enabling a wider colour gamut and fluids with larger particles and more pigment for higher opacity, colours are more vibrant and whites and blacks stronger ensuring the Xaar Aquinox can bring the latest imaginative designs and finishes to life.

Being able to handle the latest aqueous inks means the Xaar Aquinox not only delivers the impact and creativity demanded, but also helps users future-proof their business in a more environmentally friendly way. Xaar’s technology and its chevron architecture provides a very energy efficient operation, reducing the power required for printheads, printers and end users alike. In addition, the Aquinox’s improved nozzle open time and latency reduces maintenance and ink waste, helping to minimise the total cost of ownership for users.

John Mills, CEO of Xaar, said: “The introduction of the Xaar Aquinox, powered by our ImagineX platform, is our most significant product launch in recent years.

“The Aquinox demonstrates our commitment to driving the future of inkjet into new and ever more sustainable applications, and we are proud of this revolutionary transformation in aqueous inkjet printing.”

Supported by the robust and proven Hydra ink supply system, with its ‘plug and print’ capability and easy to use, intuitive user interface each Xaar Aquinox printhead is easily integrated into new print machines.

The Aquinox comes with development kit that gives OEMs everything they need to get up and running. This includes the ink supply system and printhead drive electronics.

Having collaborated with leading developers and manufacturers of aqueous inkjet inks to rigorously assess and improve performance, the Xaar Aquinox is equally capable of handling dye-based and pigmented fluids and inks, across a wide range of applications.

John concluded: “The Aquinox seamlessly combines all Xaar’s proven technologies and innovations into a truly transformational and reliable aqueous printhead, providing a real step change in reliable aqueous inkjet printing.

“From textiles to ceramics and packaging, we see the Xaar Aquinox breaking new ground, enabling new water-based print applications, many of which were previously not possible with inkjet.

“The Xaar Aquinox will revolutionise aqueous printing, helping to deliver a world where you can truly print anything you imagine.”