#Digital Printing

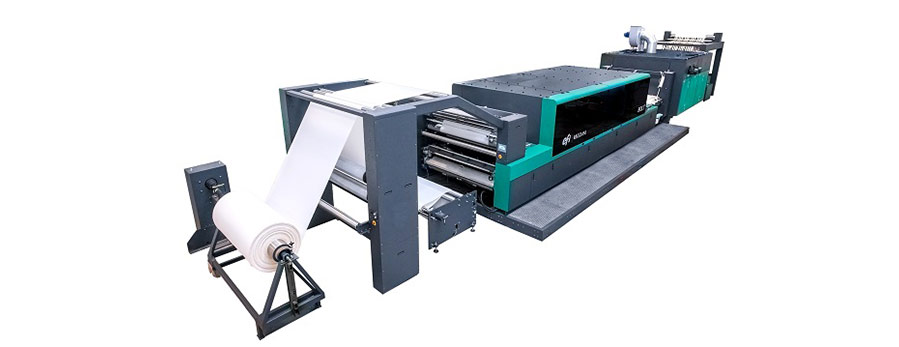

EFI Reggiani BOLT upgrade offers improved quality

Dedicated color profile creation on the newest-version EFI Fiery® BT-1000 digital front end driving the printer delivers better, more-intense tones and improves capabilities for matching existing color profiles commonly used in digital textile printing.

The enhancements are an important step in further enhancing digital printing’s presence in the industry, bringing greener, more-sustainable inkjet technologies to the fore as a replacement for analog dyeing procedures that make textile manufacturing the world’s second-largest polluting industry.

“With the industry’s top speed and now the delivery of even higher print quality, the EFI Reggiani BOLT can help spur a revolution in textile printing, migrating more production to digital technology, ensuring the fastest return on investment on high-volume work thanks to superior throughput and unmatched reliability and uptime,” said EFI Reggiani Senior Vice President and General Manager Adele Genoni.

“With the BOLT’s new enhancements – and its ability to print extremely high quality on a variety of designs and fabric types at record-breaking speeds up to 90 meters per minute – the economic cross-over point between analog and digital printing of fabrics is lower than ever before. The time for single-pass technology is now with this best-in-class, sustainable, high-quality and high-throughput digital textile print solution.”

This 1.8-meter-wide single-pass printer – the first digital textile printer to receive the Printing United Alliance InterTech™ Award for advanced print technology innovations – is well-positioned to have a major transformational impact on the industry. With its current installed base, the EFI Reggiani BOLT is already responsible for printing more than 50 million linear meters of fabric worldwide.

Faster processing and higher-quality print

Now available globally, the EFI Reggiani BOLT upgrade features hardware and software enhancements for improved overall performance, printing quality, uniformity, and increased user-friendliness including:

• Nozzle out and uniformity compensation features that improve solid color appearance and enhance overall printing quality

• Increased performance and improved processing speed for large, complex files;

• Integration of a new digital camera that both provides for precise and consistent print results and shortens the time for print head replacement and alignment;

• An enhanced user interface – based on EFI Fiery Command WorkStation® 6.0 – that is easier to use;

• Fiery Smart Ink Estimator, a key tool to help determine job profitability based on accurate calculation of ink costs prior to printing.

For more information the EFI Reggiani portfolio of leading-edge digital textile printing solutions, visit:

http://www.efi.com/reggiani.