#Digital Printing

Innovative Partnership: more revenue and customer satisfaction for Menderes Tekstil with SPGPrints’ OrtaScreen™

Menderes Tekstil, reliable partner in rotary screen printing

Founded in 1983, Menderes Tekstil has more than 30 years of experience in textile printing. The company is world leader in home textile and approved supplier of home textile products to giants in the European market: mainly printed and dyed bed linen and shirting. Menderes Tekstil is always eager for innovations in printing. That is why they value their partnership with SPGPrints. This is mutual. With a partner like Menderes Tekstil, SPGPrints always has the opportunity to test new products and technologies. This also applies to the OrtaScreen™.

Introduction of the OrtaScreen™

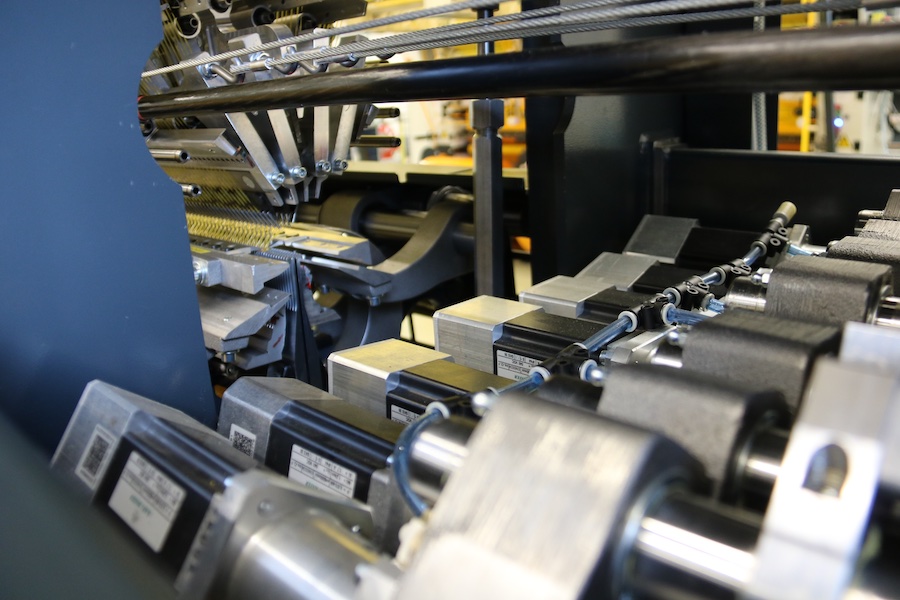

Ever since SPGrints invented rotary mesh screens in 1963, they are reinventing the screens over and over to always take the printing quality to a higher level.

Designs often make use of halftones and grids, which are based on an orthogonal orientation. Printing these designs with the common rotary screens can generate undesired moiré. Due to the reinvented mesh structure of the OrtaScreen™ moiré can be eliminated.

The orthogonal orientation of the holes brings 4 bridges together instead of the 3 in hexagonal screens. The OrtaScreen™ features a three- dimensional surface structure, allowing the paste of adjacent holes to flow together and to cover the textile substrate easily. It allows to print geometrical and halftone designs with high edge sharpness and leads to unrivaled print definition. Furthermore blotch printing is taken to a new level. This is the best available technology to get most difficult designs with highest quality.

The positive impact of OrtaScreen™

Menderes Tekstil has been using the new OrtaScreen™ for a while now. This screen replaced the previously used NovaScreen® for a substantial part. The difference between both types of screens is especially visible in the printed halftones and geometrics. OrtaScreen™ helps Menderes Tekstil to print these challenging designs. Printing these designs with an OrtaScreen™ results in higher image definition, smoother halftones and extreme even blotches. “This high-level printing quality reflects the highest standards,” explains Yusuf Güngör, Manager Engraving & Design at Menderes Tekstil.

“We greatly benefit from the usage of OrtaScreen™. Printing geometric designs, halftones and blotches with this new invented screen gives a much better quality which positively impacts our turnover and customer satisfaction,” says Yusuf Güngör.

Fruitful partnership

“Since the beginning of Menderes Tekstil in textile printing, we have been using the textile equipment of the best supplier. At that time, this supplier was named STORK. Nowadays it is SPGPrints,” says Yusuf Güngör. For his team, the partnership with SPGPrints is paying off, especially with the new local team of SPGPrints’ Turkish Office. “This relationship and the constructive attitude of SPGPrints positively affect our turnover,” says Yusuf Güngör. In the future, the focus of this partnership will be on even more innovations and technical support.

As mentioned earlier, Menderes Tekstil is always very helpful and eager to try new products and screens as a partner of SPGPrints. This innovativeness is characteristic for the company. Menderes Tekstil has been using the OrtaScreen™ ever since SPGPrints started selling it. As an innovative company, Menderes Tekstil has a clear vision for the future of textile printing. “The OrtaScreen™ will help us a lot to increase our revenue from our shirting fabric business,” says Yusuf Güngör. “In the future, we plan to use these screens in all of our textile rotary printers.”

Promising results

“This new screen really improved our printing process and results,” answers Yusuf Güngör when asked about the solutions and benefits the OrtaScreen™ offers Menderes Tekstil. “These results give us new possibilities regarding the future of textile printing. Moreover, the usage of OrtaScreen™ can provide the entire industry with strategic benefit.”