#Digital Printing

Killing Eve sparks pursuit of digitally printed pyjamas

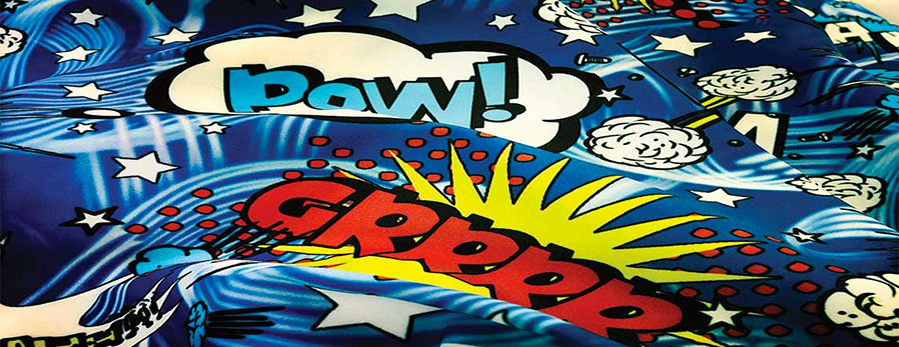

When Jodie Comer’s habitually glamourous character, Villanelle, stalked the streets sporting pop-art inspired kids’ pyjamas in season two of the BBC’s Killing Eve, viewers caused a social media storm trying to track down the night-time attire.

Fans of the show soon traced the bold pyjama design to Friedmans, a design studio and printed fabric supplier based in Greater Manchester, UK. According to the company’s design manager, Nick Thomas, the initial order was placed by Killing Eve’s production company, Sid Gentle Films, through Friedmans’ Funkifabrics web-to-print website: “It was as much a surprise to us as anyone else that our design ended up in the limelight. It only really came to our attention when we saw the interest on social media after the first episode had aired.”

What could have been an expensive and time-consuming task for Killing Eve’s production team was made simple by Friedmans, providing a case-in-point on the benefits of digital production in the world of fashion. When Killing Eve’s costume department decided against off-the-peg for this particular ensemble, they started exploring fabrics and quickly landed on an apt design. Stretch fabric was key to the storyline, to make the outfit appear tight on Comer, as if she was wearing children’s pyjamas, but retaining her freedom of movement. The pyjamas were also finished with red trim at the cuffs to highlight how short they were.

By using Mimaki digital production, Friedmans’ Funkifabrics offers customisation of the fabric choice, the scale of the design and run lengths from just 0.5 meters – all with speedy lead times.

Consequently, Sid Gentle Films were able to produce a one-off bespoke pair of PJs that stood their ground amongst a collection of looks from a television show commended for its outlandish and luxurious fashion choices. The Los Angeles Times even quoted Comer as saying: “I think it’s my favourite outfit of the whole series.”

Villanelle’s iconic pyjamas were printed by Friedmans on a Mimaki TS300 dye sublimation printer (purchased through authorised Mimaki partner, R A Smart), before being transferred using a rotary heat press onto polyester-lycra blend fabric.

The unexpected surge of attention has been welcomed by Friedmans: “We were delighted to see the print receive such a positive reaction – especially as the show is so synonymous with great costume design,” enthuses Thomas. “Thanks to our ongoing investment in wide format textile print technology and software, we are continuing to grow as a business, reaching an ever more varied customer base. Combining this with a forward-thinking workflow, we can focus on providing on-demand delivery for customers big and small. The vibrant, customised pyjamas worn by Comer in Killing Eve are a perfect example of what can be achieved when great vision, talented design and first-rate technology come together – it’s tremendously satisfying to see such an impactful end result.”