#Denim

EIM presents the first global report on the environmental impact of denim finishing

It offers a comprehensive view of the industry, setting new sustainability benchmarks and guiding the transition toward more responsible production.

The findings reveal improvements in resource efficiency while underscoring the urgent need to reduce harmful chemicals and practices that threaten both worker health and the environment.

The report reveals that 63% of the analyzed processes are already classified as low environmental impact, reflecting a positive shift toward more responsible practices. However, it also highlights critical challenges, such as the high use of hazardous chemicals (24% of processes), particularly pumice stones and potassium permanganate—practices that urgently require safer and more sustainable alternatives due to their negative effects on both the environment and worker health.

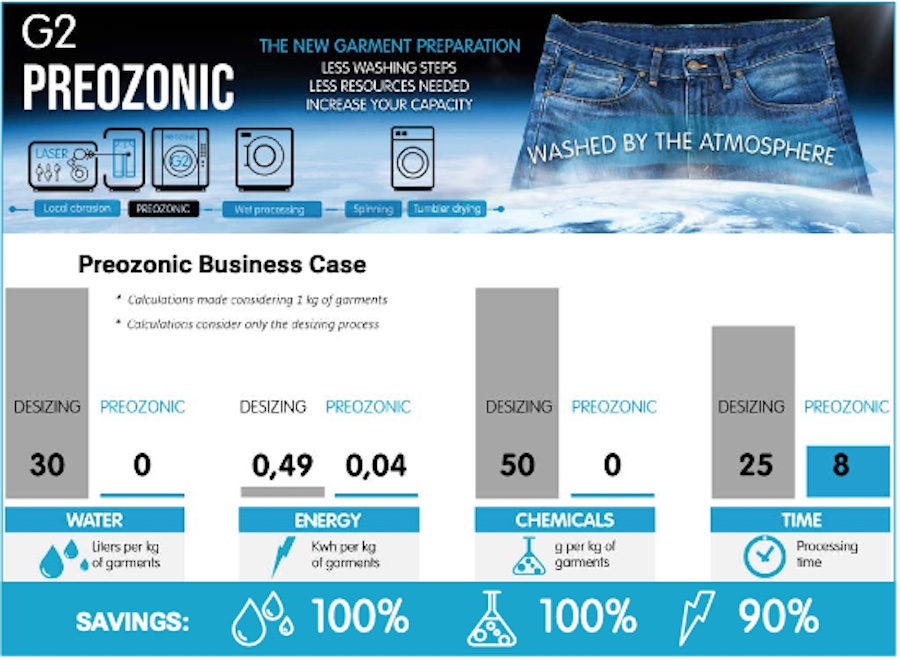

Progress in water consumption management is also considered, as this remains one of the key environmental challenges for the textile sector. The report shows that the current average water usage in denim finishing is 30 liters per garment—still above the recommended benchmark of 22.5 liters per garment. Effective strategies for reducing water consumption include optimizing rinsing processes, selecting fabrics that require less aggressive treatments, and implementing technologies such as ozone, e-flow, and smart foam systems.

Among the proposed improvements are also the adoption of advanced technologies to reduce chemical use and protect worker health, such as the strategic selection of ZDHC-certified chemicals and the automation and digitalization of manual processes.

Begoña García, creator of the EIM platform and co-author of the report, states: “For years, the textile industry has lacked reliable tools to measure its environmental impact, making data-driven decisions difficult. This report marks a crucial step toward transparency and continuous improvement, showing that technology is key to measuring and reducing environmental impact.”

The report aims to support informed decision-making based on verifiable data, positioning EIM as a global standard essential for transparency and ongoing sustainability improvements in the textile industry.

The full report is available for download and will be updated annually, serving as a vital tool for brands and suppliers to collaborate in reducing their environmental footprint and advancing toward a more responsible and sustainable production model.

To access the full report, visit Innovations & Challenges in Denim Finishing – 2024.

https://tinyurl.com/mbehwym5