#Denim

The Denim for the FUTURE – the one produced in a sustainable way – is already possible

For these reasons, the world community of consumers hope that denim producers put more efforts to update their dyeing machines and to adopt new eco processes and everything else that may help to reduce not only water consumption, but, mainly, chemicals, for a more economical, versatile and, above all, sustainable production.

Concerning indigo and sulphur dyes dyeing for denim warps, Master has started since many years, first among all the machine producers, the path towards sustainability of processes.

During the last twenty years, Master, thanks to the research and experimentations with its own pilot plant, and thanks to the cooperation with established customers, which are among those well known for their highest reputation worldwide, has built 13 dyeing modules – installed in five dyeing lines in different mills – based on the innovative and ecological nitrogen technology (Pat.).

Achieved results have unanimously confirmed the exclusive advantages, including quality, economy and sustainability, assured by the new dyeing process, along with the possibility to develop new exclusive effects, not achievable on traditional dyeing machines.

The key point of this new technology is based on the fact that, thanks to nitrogen atmosphere, indigo reduction is full and perfect and the leuco particles have nanometric dimensions improving the dyeing performances. This special leuco conditions brings to a better color fixation compared with traditional dyeing methods in air, assuring advantages in terms of fastness, intensity and brightness, giving the fabric a higher quality level.

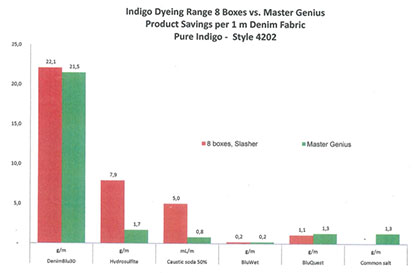

Working in a sealed inert atmosphere, like it is with nitrogen, avoids the typical problems of the classic dyeing in normal air, allowing to reduce by more than the half the dye bath volume, the number of dips and, consequently, the skyers, resulting in a drastic reduction of consumption of caustic soda and hydrosulphite (up to 70%). Furthermore, the improved color fixation allows a significant saving in water for washing, which is, nowadays, another top and relevant issue.

Similarly, also in case of suplhur dyeing, especially black, a better dye stuff efficiency is evident and it can be visually estimated about +40%, compared with traditional dyeing methods. Furthermore, a much better fixation and brightness can be achieved if compared with results from traditional machines.

It is clear that this innovative dyeing system is the only one that can be considered actually “ecological” as it is the only one that directly brings to the reduction of dyeing bath volumes, the number of boxes and skyers with the consequent drastic cutting in dangerous chemicals, water and power.

Further, it is important to underline that this new dyeing system allows, in any case, to play with all those typical parameters - physical, chemical, mechanical and technical – of dyeing processes to achieve the desired final results.

Unfortunately, since the starting of their first introduction, these dyeing modules based on nitrogen technology have not spread as expected due to a few reasons, the first one, the lack of technical knowledge and the underestimation of the enormous advantages they were offering by the potential utilizers.

In fact, many producers, although sensitive to ecology, have believed that they could achieve the desired eco-targets by simply applying some devices to their machines, such as ultrasound, etc., which are, actually, only palliatives capable to bring limited improvements, but nothing that can allow the reduction of dangerous and polluting chemicals.

Even if this new modern and adequate nitrogen technology is available, analyzing today denim production situations it comes out very clear that, despite everyone making of ecological issues their banner, the majority, or rather almost all, of the denim on the market, is still dyed with the old classic method in open air, that is to say, anti- ecological.

Considering what above described, it is evident that, in the globalized environment we are working, it is not possible to continue in the same way we are today doing.

Denim producers have to face the imperative ecological and moral obligation to change their production mentality, to innovate/update their classic dyeing machinery to reduce the consumption of chemicals, water and power and to adopt everything necessary to offer ecological and sustainable products, achieving, by the way, cost reduction advantages.

Concerning ecology issues, among the most urgent worldwide, many consumers protection organization are asking for an international law, to be introduced as soon as possible, to impose the reduction of consumptions and the respect of regulations to protect health and the environment. Of course, a transition period has to be considered, from the present technology to the one respecting the imposed ecological targets, so that no commercial problems can arise.

Well aware of these issues, Master, thanks to the passion for innovation and the unique experience achieved with the construction of approximately 80 dyeing ranges, and thanks to the availability of a pilot dyeing machine in its own laboratory, has carried out a number of studies, tests and experiments with the target to design a new dyeing machine, simple, economical and versatile, capable of dyeing both in air, as per traditional method, and in nitrogen atmosphere, as per new technology.

Thanks to the success of all these experiments, during ITMA 2023, Master has celebrated the 60 years of activity announcing the launch of two new machines with this extraordinary flexibility of dual-technology, both for slasher and rope dyeing systems.

These two new machines, when working in air as per traditional system, allow to replicate all the styles already running with the same characters, while working with nitrogen they bring the possibility to develop new exclusive and inedited styles with better quality, less costs and, above all, eco-sustainable.

These new machines are proudly identified by the prefix “CRAFTY” to re-confirm their operational geniality. “Craftyflow” and “Craftyrope” (Pat.) are the most innovative dyeing ranges for indigo and sulphur dye for denim warps today available.

They are the result of long tests and experimentations aiming to transfer the concept of dyeing in nitrogen atmosphere of the original modules, complex and expensive, in a new simple and original dyeing box, versatile and more economical, that represents the future, even if maintaining the connection with tradition and the past.

These particular machines, thanks to the ingenious dual operating mode, depending on their configuration, can indifferently perform:

a) Indigo dyeing, as per traditional method in air, with all the box at full level and low concentration. These processes can be completed with bottoming, topping and sandwich dyeing using nitrogen technology with all the related advantages and with results never achieved before.

b) Indigo dyeing, in the new way, in nitrogen atmosphere and with all the box, same as per a), but at low dye bath level, that is to say only one/third of the regular total dye bath volume, with the advantage of multiplying by three the dye bath circulation and, thus, the contact dye bath-yarn, allowing color intensities aligned with the highest values.

c) Indigo dyeing, in the new ecological way, with nitrogen technology, using only the half of dyeing boxes, at low bath level and higher concentration, and only one/sixth of the traditional dye bath volume, achieving the following advantages:

- 50 to 70% reduction in caustic soda and hydrosulphite consumption

- 30% reduction of power consumption

- In case of slasher machine, by-pass of half of dyeing boxes and related skyers, with consequent 50% reduction of yarn wastage at lot change.

- Thanks to dye bath reduction, the number of bath changes in boxes is multiplied by six, increasing the exchange bath/yarn and improving dyeing quality.

- Possibility to produce new, original and exclusive styles, not achievable on standard machines

- Sulphur dyeing without the necessity of steamer.

To be noted that there is absolutely no nitrogen consumption during the dyeing process, except for the initial filling.

As far as concern to investments, the new “CRAFTY”, compared with a traditional dyeing machine in air, even if in the most flexible and complete version, involves an extra cost that can be recovered in a very few months of production running.

Finally, aiming to make the easiest is possible the passage to more sustainable processes, Master has developed the possibility to transfer the advantages of nitrogen technology (as above described point c) also on already installed machines, both “slasher” and “rope”.

In general, this upgrade can be installed directly on site, and in the most simple and economical way, on rope dyeing machines, as, the typical construction of the dyeing boxes is not requiring their substitution but only an integration.