#Composites

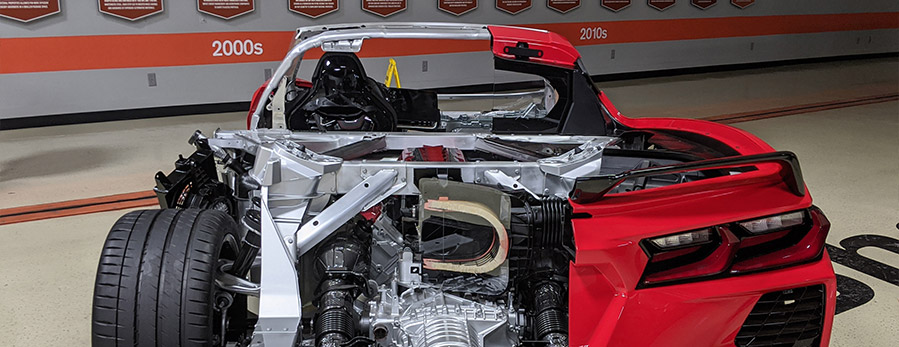

TTI machine technology enables curved carbon fibre rear bumper beam for iconic Chevrolet Corvette Stingray

The Chevrolet Corvette Stingray has always made extensive use of composite materials in its construction, and the launch of General Motors’ (Detroit, Mich., U.S.) new 8th generation flagship car, with a carbon fibre bumper beam and mid-engine layout, continues this strategy. With the first two years of production sold already, the TTI and Shape Corp. process is well placed to support GM’s production requirements, with the new Radius Pultrusion line delivering an annual production capacity of 70,000 parts.

TTI set up the initial process on its prototype line, and optimized fibre and fabric guide systems to feed the complex set of reinforcements into the chrome plated steel Radius Pultrusion moulds. As pultrusion places particular stresses on the reinforcement fabrics used, TTI also suggested modifications to the selected carbon multiaxials to maintain perfect fibre alignment in the part and improve production line speed.

The highly automated bumper beam production cell installed at Shape Corp. controls a complex set of reinforcements including carbon fibres running from a creel, biaxial, triaxial and stitched unidirectional carbon fabrics – all with glass surface tissues for stabilization and a better surface finish.

“TTI’s Radius Pultrusion provided the perfect advanced composites solution for an extremely challenging bumper beam requirement in the Corvette Stingray. With TTI providing a

complete technology package of machinery, process development and exceptional technical support, the Corvette Stingray project has been a great success for Shape Corp. and TTI,” commented Toby Jacobson, Plastic Materials & Process Manager, Advanced Product Development, Shape Corp.

The curved, multi-hollow carbon fibre rear bumper beam produced for the Stingray

showcases Radius Pultrusion’s unique ability to form complex curved profiles for highly structural applications, within a compact machine space. TTI has developed this concept further with the recent launch of its ultra-compact pullCUBE pultrusion machine. At only 3.5m in length, pullCUBE is around 75% shorter than traditional machines making it a highly transportable and space-efficient option for both curved and straight section pultruded parts.

General Motors Co. and tier one Shape Corp. recently won the PACE Innovation Partnership Award for the development of this first curved pultruded automotive part.