#Composites

Hexcel’s complete composite solutions for marine at JEC World 2020

Hexcel offers a comprehensive range of DNV GL approved multiaxial fabrics, woven reinforcements, and prepregs aimed at builders of high-performance racing yachts and luxury yachts. Hexcel materials are used for hull and deck structures and for masts and appendages on the most advanced composite marine structures, including racing yachts for the America’s Cup and IMOCA class.

Innovations on display include:

- Hexcel’s HiMax™ Carbon Multiaxials and PrimeTex® Woven Carbon Fabrics for Gunboat 68. A scale model of this fast, technologically advanced and elegantly designed sailing catamaran will be on display, illustrating how HiMax™ reinforcements are used to infuse the hull and deck structures of this stunning series-built yacht. Hexcel supplies an optimized package of carbon fiber multiaxial fabrics with fiber weights, fabric architecture, and product width specifically tailored to Gunboat’s epoxy infusion build process. Hexcel PrimeTex® fabrics are used as the outermost layer in the yacht’s construction with the patented fiber spreading process producing a flatter and more uniform surface finish.

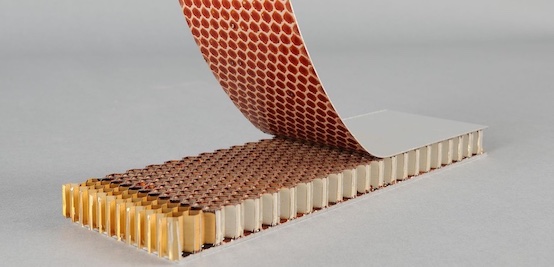

- New HexBondTM Low-Temperature Adhesive Film. HexBond™ 679 is a 250gsm epoxy adhesive film formulated to be fully compatible with the HexPly® M79 prepreg range. Fully cured in only four hours at 80?, this prepreg adhesive film system offers huge cycle time reductions, provides strong lap shear and peel strength performance, and delivers outstanding mechanical properties in foam and honeycomb sandwich structures.

- HexPly® M79 Prepregs for Short Cycle Times. HexPly® M79 prepregs can be cured at 70 Celsius for eight hours or 80 Celsius for four hours, increasing build rates with reduced heating and cooling times. When combined with Hexcel’s innovative air venting grid technology, HexPly® M79 UD carbon tapes can be laminated with reduced debulking steps to produce void contents <1%, irrespective of laminate thickness. With consistently low void contents and improved mechanical properties, naval architects and marine design engineers are now able to further optimize highly loaded composite structures.

- HexPly® XF2 Surfacing Prepreg and HexPly® SuperFIT™ Prepregs. Hexcel will demonstrate the exceptional surface finish provided by HexPly® XF2 surfacing prepreg as it exhibits a hardtop sun canopy section from a leading U.K. superyacht builder and a small-scale hull superstructure component.

HexPly® XF2 is a highly drapable single ply prepreg surfacing solution. With a tacky surface for excellent adhesion in the mold and an integrated structural layer providing huge lay-up efficiencies, HexPly® XF2 delivers a high-quality pinhole-free finish straight from the mold, reducing finishing and paint preparation time significantly.

The superstructure component on display also features carbon fiber HexPly® SuperFIT™ prepregs (semi-pregs) providing structural strength below the carbon fiber XF2 surface layer.

Hexcel’s SuperFIT™ products are only partially impregnated with one dry face and one tacky face for easy positioning in the mold, holding each ply to the next. The air pathways in the dry fabric face facilitate the removal of air or volatiles from the laminate, minimizing voids without time consuming debulking steps. For marine applications, the use of HexPly® M79 SuperFIT™ prepregs allow rapid cure cycles at low temperatures and are easy to process in conjunction with conventional HexPly® M79 prepregs.

- HexTow® HM54 Carbon Fiber - Hexcel’s carbon fibers provide leading strength and modulus in highly demanding applications. Following the legacy of dependable HexTow® carbon fibers like IM2C, HM63, IM8 (which has been selected for solid carbon rigging for all teams in the 36th America’s Cup) and others used in marine applications, Hexcel has developed a new high modulus fiber, HexTow® HM54. This new fiber offers a higher stiffness that is ideal for applications like masts and foils in the marine industry.

Hexcel’s marine innovations will be on display on the Hexcel booth at JEC World 2020, Hall 5, Booth J41.