#Carpets

Erhardt+Leimer at DOMOTEX 2020

The segmented roller guider system SWS 9430 is a digital web guiding system in a pedestal design for the exceptionally gentle alignment of practically all textile webs. Thanks to the center support it is available for widths of up to 7200 mm.

The guiding slats divided in the middle permit spreading of the web during guiding without forming longitudinal creases prior to processing. Subsequent spreading devices such as bow rollers are therefore unnecessary. In addition to guiding and spreading, web width measurement, web offset and oscillation are also possible, if required. For the detection of the web edge or center, FE 47 wide band sensors are used.

The compact design of the SWS 9430 makes it particularly suitable for use e.g. in coating unit infeeds or at the exit of accumulators. The ELSMART systems can be custom-designed on request and can be fully integrated into the sides of a machine in a wide variety of machine types.

Besides the segmented roller guider, another device is available for guiding large-width textile webs such as technical textiles and carpets: the classic pivoting frame. However only the segmented roller guider makes it possible to spread the web at the same time, and it usually requires considerably less space.

ELGUIDER DRS 71 is a web guiding system with a rugged frame design, integrated control technology and separate operating unit for optimized web corrections. It can be used with a web tension of up to 2000 N (special version up to 5000 N).

Depending on the material, infrared or ultrasonic sensors are used to detect the web position. Manual or motorized positioning systems adjust the sensors to the given web width.

The digital position controller is integrated into the pivoting frame. The control parameters are easy to adjust on the user-optimized operator interface or via the E+L software tool ELBUDDY. This also optimizes the control loop.

All functional modules of the control system have a CAN bus interface through which they are networked. Thanks to this setup it is very easy to adjust the E+L guider to the requirements of new tasks, interference immunity is very high and cable complexity reduced to a minimum.

E+L offers various interfaces with standard protocols for connection to different bus systems or to a PLC / industrial PC.

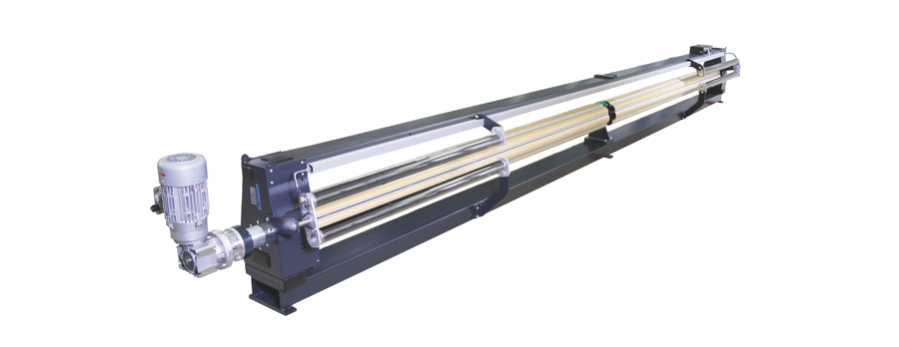

The ELCUT BTB 01 web cutting devices trim moving fabric webs at the edges to the exact width required. The proven shearing cut principle with powered top and bottom blades ensures a precise cut and clean-cut edges.

The user can choose from different blade sets to suit specific materials. One of these blade sets is particularly suitable for thick materials, such as carpets or felt, as the top and bottom blades are designed as cup wheel blades.

The top and bottom blade shafts, mounted in bearings at one end, are driven by a three-phase motor via a multi-stage spur gear. Various gear ratios permit the choice of different cutting speeds. The cutting speed can also be steplessly adjusted to the production speed using frequency-controlled three-phase drives.

The motor can be mounted on the inside or on the outside.

The unit is predominantly installed after the last process step before rewinding. It can be used for horizontal and vertical web travels. A range of support beams is available for manual or motorized positioning.