#Sustainability

Jeanologia presents system that easily identifies fabrics suitable for treatment with sustainable technologies

It creates a study that analyzes the fabric’s reaction to sustainable processes, specifically laser, to achieve the desired look and washes with reduced water, chemical and energy consumption. Thanks to this tool it is possible to considerably reduce the environmental footprint of finishing processes.

The project manager of Jeanologia, and specialist in finishings Begoña García, has a talk on “Washing denim in the XXI century. Fabric selection to succeed”. García makes available to the industry the new standardized analysis that allows optimization of finishing processes, showing a priori the creative possibilities of a material. LSF also allows a prediction of the environmental impact caused by finishing processes.

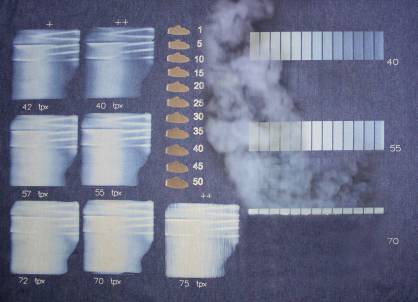

“It is key to choose the right material for using with laser technology because each fabric has different properties leading to different results. By optimizing the finishing process and knowing the reaction the fabric will have a priori, this test helps us to know if the use of laser is enough to get the wash or look desired”, explains Begoña García. Thanks to the LSF we know which fabrics have a good reaction to laser (Light Sensitive Fabric) without the need to combine it with traditional dry processes.

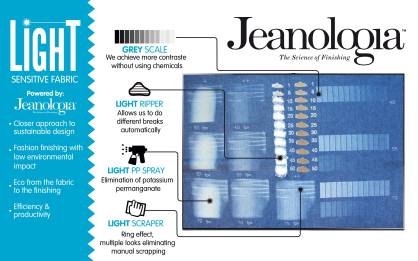

This tool classifies the fabric with regard to its reaction to laser, evaluating the grey scale, the efficiency in the imitation of natural tears and the visual evolution with Jeanologia’s Light Solutions. Among which is the Light PP Spray, that avoids the use of noxious potassium permanganate or Light Scrapper, which substitutes manual bleaching.

Jeanologia’s innovative system responds to the needs of fabric suppliers, weavers, brands and laundries that work together to achieve garment finishes in an efficient and sustainable way.

The MFC (Man-Made Fibers Congress) taking place in Dornbirn (Austria) from September 13 to 15, with 800 participants from 30 countries and with 100 talks focused on innovation in fibers, textiles and fabrics. The 56th edition of the congress will pay special attention to sustainability, emissions reduction, ecological treatments and liquid residue management.

- The new Light Sensitive Fabric (LSF) test identifies which fabrics are most suitable for achieving fashionable finishes (natural and vintage) with a low environmental impact, avoiding the use of traditional and noxious techniques such as manual scraping and potassium permanganate spraying.

- LSF optimizes the production process and is an indispensable tool for fabric manufacturers, laundries, designers and brands that work together in achieving desired finishes in a sustainable way.

- More than 800 experts from the textile industry will participate in the largest international congress in the field of chemical fibers.