#ITM 2016

ITM - highlights from Saurer Schlafhorst and Saurer Zinser

The new Autocoro 9 with its intelligent individual spinning position technology sets new records for energy consumption, productivity, efficiency, ease of operation and quality. The machine outperforms its legendary predecessor with sensational output data: 25 % lower energy consumption, 19 % reduction in spinning costs, proven rotor speeds of 180,000 rpm, take-up speeds of 300 m/min and a 60 % lower servicing outlay. The Autocoro 9 is thus the production platform of the future.

The semi-automatic BD 6 machine is also in a league of its own, producing packages in Autocoro quality across the entire range of yarn counts and with package sizes of up to 320 mm in diameter. Its low energy consumption, rapid take-up speeds of 230 m/min and high piecing reliability cut spinning costs and increase the profitability of spinning mills.

Ring spinning machines from Zinser: a new level of efficiency in the commodity business

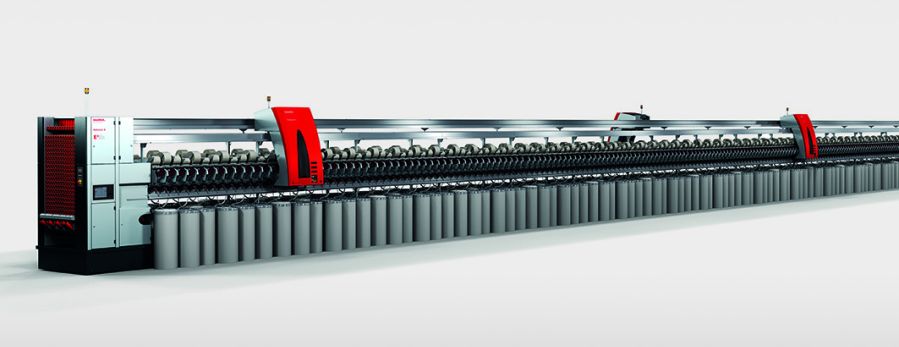

At a length of 2016 spindles, the new Zinser 72 ring spinning machine breaks the 2000-barrier and sets new standards for efficiency in the commodity business. The machine is super-long, super-economical and extremely user-friendly. It lowers production costs by up to 11 % and has a footprint that is up to 21 % smaller compared with shorter rival machines. The new two-end TwinSuction system saves two-thirds of the energy consumption in combination with the sensor-controlled OptiSuction yarn break suction system.

The ZinserImpact 72 compact spinning machine is equipped with the self-cleaning Impact FX unit and guarantees top productivity and optimal raw material utilisation.

The new ZinserSpeed 5A speed frame boasts an energy-saving mode for suction and flyer table blowing that shaves 20 % off the total energy consumed. In 220 gauge the speed frame is also up to 17 % shorter than its predecessor. With a doffing time of less than two minutes, the ZinserSpeed 5A ensures maximum production efficiency.

Intelligent sensor technology, smart process control, autocalibration and functionally optimised processes turn the new Autoconer 6 into an automatic package winder that pushes the textile-technological limits, winding at the most productive settings virtually without the need for operators. Innovations such as LaunchControl, SmartCycle, SmartJet and Speedster FX boost productivity by up to 12 % compared with the previous model. The new Eco-Drum-Drive system, SmartCycle and the intelligent vacuum control system "Power on demand" reduce the energy consumption on the Autoconer 6 by up to 20 %. The machine maintains its considerable lead in value creation with the Autoconer package remaining the benchmark for quality and added value in downstream processing.

Plant Operation Center: POC - big data for greater efficiency Spinning mills with POC, the Schlafhorst and Zinser Plant Control System, can use their production and quality data to improve efficiency. Service intervals can be optimised and production downtimes and quality problems avoided by prompt intervention when using the new Off-Standard analysis.

Customer Support: SUN – SERVICE UNLIMITED

With the innovative SUN - SERVICE UNLIMITED service concept, Schlafhorst and Zinser offer their customers support in their day-to-day operations that is unmatched by any other manufacturer. Over 500 service staff in 20 service stations and 3 technology centres advise customers all over the world with regard to productivity and quality increases as well as energy conservation. With their unique know-how they help customers to master textile-technological challenges and to gain a lead over their competitors. The ecommerce platform SECOS 2.0 guarantees minimum response times in the delivery of original spare parts.

And in SUN-PLAN Schlafhorst has developed a new service concept that is unique within the industry: Individual service at a fixed Price.