Yarn & Fiber

Teijin Carbon and A&P Technology launch high-performance BIMAX TPUD braided fabric for scalable composite manufacturing

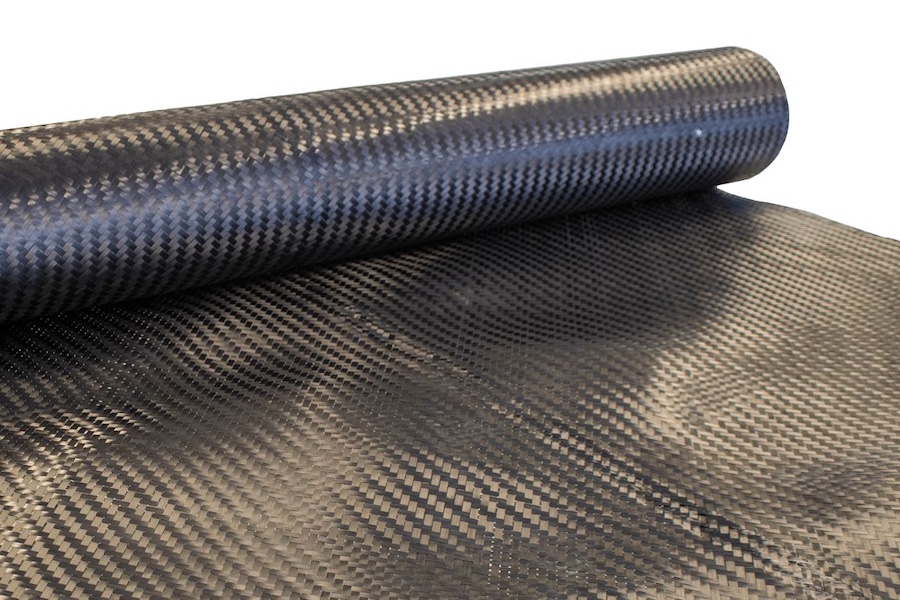

Teijin’s Tenax™ TPUD IMS65 PAEK – a high-quality UD tape based on polyaryletherketone (PAEK) resin is slit into narrow widths and braided by A&P Technology into a 65” wide +/-45° fabric. The +/-45° braid architecture has minimal crimp- offering a high translation of tape properties while providing excellent drapability for complex geometries. With a fiber areal weight of just 184 gsm and 34 percent PAEK content, IMS65 PAEK Bimax® enables out of autoclave (OoA) processing and vacuum bag only (VBO) consolidation, significantly reducing manufacturing time while enhancing mechanical performance and impact resistance.

Features and benefits of IMS65 PAEK Bimax® fabric:

+++ High fiber volume and low crimp for superior mechanical performance

+++ Extreme drapability for deep-draw parts

+++ Reduced lay-up time per layer – 65” wide fabric enables quick laydown of biaxial reinforcement

+++ Native air evacuation pathways for optimal consolidation of thick components

+++ Room temperature preform placement with spot tacking to simplify production workflows

This innovative braided fabric meets or exceeds the properties of existing

National Center for Advanced Materials Performance (NCAMP)-qualified PAEK prepregs, offering a robust and scalable solution for next-generation composite structures. The combination of Teijin Carbon’s advanced thermoplastic UD tape technology and A&P Technology’s expertise in braided fabric manufacturing delivers a truly high-performance solution for modern composite applications.