#Yarn & Fiber

The LYCRA Company previews bio-derived LYCRA® EcoMade Fiber at ISPO

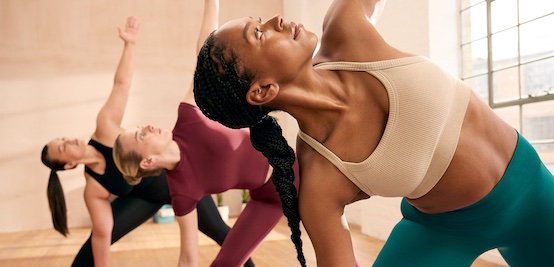

Bio-derived LYCRA® EcoMade fiber won two ISPO Textrends Awards for Fall/Winter 2026/27. In the fibers and insulation category, this renewable elastane won a “Top 5 Award,” and a garment made with the same fabric was recognized as a “Selection” in the pants & tights category. The Brazilian activewear and swimwear brand LIVE! produced the fabric and leggings using preview samples of this highly anticipated fiber.

Launching in 2025, bio-derived LYCRA® EcoMade fiber will be the world’s first large-scale commercially available renewable elastane. The award-winning product previewed at ISPO contains 70 percent renewable content and is certified under the USDA Bio-Preferred Program. The fiber delivers equivalent performance to the original LYCRA® fiber, and no re-engineering of fabrics, processes, or garment patterns is required.

“We believe bio-derived LYCRA® EcoMade fiber represents an exciting future where we can make real, transformative change in the industry without sacrificing performance,” said Steve Stewart, The LYCRA Company’s chief brand and innovation officer. “We are thrilled to receive this recognition from ISPO and applaud our customer LIVE! for creating the award-winning fabric and garment.”

The LIVE! brand is renowned for its high-quality, sustainable apparel, and its UpFit Capsule Collection includes the ISPO award-winning leggings, Bermuda-length leggings, a top, and a jumpsuit. These garments made with bio-derived LYCRA® EcoMade fiber provide exceptional comfort, fit, and flexibility with the added benefit of being a more sustainable fiber.

“At LIVE!, we believe the future of fashion must balance innovation with environmental responsibility,” said Joice Sens, founder and creative director at LIVE!. “This collection embodies the spirit of LIVE! FUTURE, our sustainable innovation lab, and highlights the importance of partnerships like this one with the LYCRA® brand, enabling us to develop products that combine cutting-edge technology with reduced impact."

Steve Stewart is presenting “All In: The Power of Partnership” on ISPO’s Green Stage on December 4 at 16:00 CET. His presentation details how collaboration has been critical to commercializing bio-derived LYCRA® EcoMade fiber and bringing it to market.

Visit The LYCRA Company’s ISPO Event Page for show information and to discover the range of sustainable solutions fueling its exhibit: COOLMAX® and THERMOLITE® EcoMade fibers made from textile waste, and LYCRA® FiT400™ fiber designed for circularity, are made with the planet in mind. To learn more about bio-derived LYCRA® EcoMade fiber, visit this webpage for product information.

https://www.lycra.com/en