#Yarn & Fiber

RadiciGroup, a pioneer in physical and digital nylon traceability

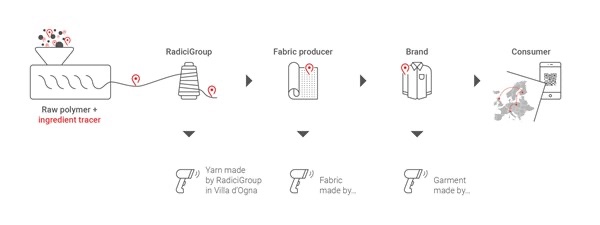

Product traceability is a key element in guaranteeing transparency along the entire supply chain, as it means each stage of production – from spinning to weaving and from packaging through to retail – can be monitored and recorded.

The project, made possible by a partnership with FibreTrace, allows manufactured nylon yarns to be traced both physically and digitally. In fact, RadiciGroup inserts a tracer (an inorganic additive) that is uniquely associated with the yarn and remains identifiable throughout all stages of processing – on both the fabric and the finished garment. Naturally, the tracer does not alter the esthetical, functional and technical performance of the yarns in any way.

In terms of digital traceability, during the production stages a scanner detects the presence of the tracer and can transmit the data relating to provenance onto a dedicated digital platform.

Finally, the consumer, via a QR code, can access the digital platform that provides all information concerning the provenance of the product and its journey through the supply chain.

“This project is the result of almost two years’ work by our Research & Development team. We’re very proud to bring to the market the first physical and digital nylon traceability solution and we plan to extend this initiative to other fibres produced by the Group,” emphasised Filippo Bona, R&D Manager of RadiciGroup Advanced Textile Solutions.

Traceability boosts consumer awareness of where clothes are really produced so people can make more sustainable buying choices. Moreover, traceability helps combat counterfeit goods and encourage products that are made in Europe, in line with the principles of Digital Product Passport Regulations promoted by the European Union.

At a time when sustainability has become essential for the fashion industry, RadiciGroup is placing its know-how and chemical knowledge of materials at the disposal of the sector’s future workers. For this reason, several outfits created by the young designers at POLI.Design are exhibited at the fair. The school, part of the Politecnico di Milano, is an internationally regarded centre for postgraduate training.

The talented youngsters were asked to design garments with some of the Group’s innovative yarns, such as Radilon® Chill-fit and Biofeel® Eleven. The first of these is a new RadiciGroup yarn that optimises the comfort and freshness of textiles, ensuring “thermal regulation” without the need for additional treatments; this was why Anna Bertini selected it to create a cycling suit, which maximises breathability and protection from UV rays. Biofeel® Eleven, meanwhile, is a wholly natural yarn with unique technical performance qualities, such as reduced water absorption, greater lightness and increased resistance. Ya - Sheng Yu used it to create an outdoor jacket that combines fashion trends in its design and colours with durability and an attractive tactile sensation courtesy of the RadiciGroup yarn. At the fair the young designer is also showing an outfit made from Renycle® recycled nylon yarns.

This collaboration bridges the gap between emerging designers and producers of materials, such as RadiciGroup: while the young talents bring creative freshness and innovative perspectives, RadiciGroup offers its experience and cutting-edge technology in the field of sustainable yarns. The aim is to create garments that not only embrace contemporary fashion but also respect the environment and are long-lasting.

“With a view to a future where the textile industry has less environmental impact, we are positioning ourselves as a strategic partner for our customers in areas such as the circular economy and innovation, offering practical and applicable sustainability solutions,” stated Bernardo Staiano, Business Area Manager, Apparel&Technical, for RadiciGroup Advanced Textile Solutions. “This is a path we undertook several years ago, which we want to continue to strengthen, collaborating with all the players in the supply chain to offer the consumer quality solutions that have less environmental impact and are, of course, traceable.”

RadiciGroup is taking a leading role at the fair, with a speech entitled "Sustainability Made Real in Synthetic Fibres" taking place on 23 April at 1pm at “Denim Talks”, Hall 8.0 (hall 8, ground floor), booth D20.