#Research & Development

CELLUN - a fiber composite made from biopolymers

Organosheets are increasingly being used within the fast-growing segment of lightweight fiber composite construction. Organosheets are pre-consolidated semi-finished sheet products with a matrix of thermoplastics and various reinforcing fibers in a wide variety of textile designs. The thermoplastic matrix allows the organosheets to be processed using industry-established "fast" processes such as hot pressing, thermoforming, injection molding with organosheet inserts, or pultrusion. The processes produce highly recyclable, highly functionalized components with reproducible quality.

The textile reinforcement of organosheets consists mainly of glass, carbon, basalt or aramid fibers. These fibers have high stiffnesses and tensile strengths, but are energy-intensive to manufacture and recycle and can only be recycled in an increasingly low-grade condition.

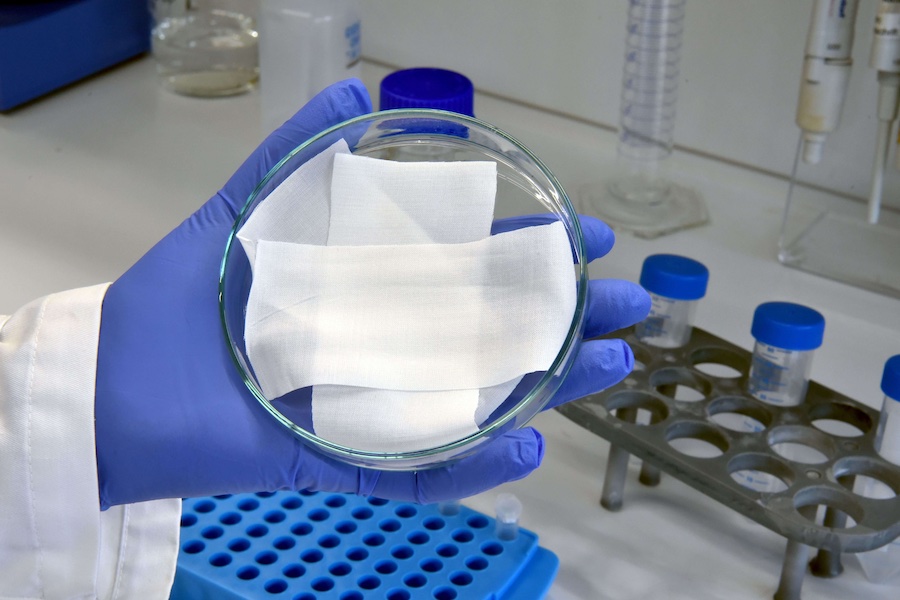

In contrast, the CELLUN composite developed at DITF is a much more sustainable alternative. For the production of CELLUN, the reinforcing component is combined from non-fusible cellulose fibers as well as thermoplastic derivatized cellulose fibers as matrix to form a hybrid roving. The cellulosic reinforcing fibers used are regenerated fibers from the company Cordenka and the HighPerCell® cellulose fibers developed at DITF.

CELLUN is now being further developed to industrial maturity as part of a joint project funded by the German Federal Ministry of Economics and Climate Protection (BMWK). The tasks of the DITF in the CELLUN joint project are primarily the production of suitable cellulose-based reinforcing fibers and the embedding of the fibers in the thermoplastic cellulose derivative matrix. The material is further processed in the in-house pilot plants into technical hybrid rovings and hybrid textiles. Using pultrusion and thermoforming processes or injection molding, molded parts can finally be produced that illustrate the technical application possibilities of the new material.

In the further course of the project, the focus will be on the complete recycling of the CELLUN material after the end of life (EOL). Two different approaches are being researched for this purpose. On the one hand, it is possible to thermally reshape CELLUN molded parts without any loss of quality. A second possible approach is to chemically separate the CELLUN material into its individual components again. These can then be used again 100% as new starting materials.

The novel CELLUN materials will offer a real advantage in the market for semi-finished technical products as an environmentally friendly, resource-conserving and cost-effective alternative to established composites in the lightweight construction and automotive sectors. By using renewable biopolymers, CELLUN will make a significant contribution to environmental and climate protection: on the one hand, conventional crude oil-based plastics can be substituted, and on the other hand, CELLUN reinforcement and matrix fibers can be produced with only low energy input and from natural raw materials.