#Yarn & Fiber

100% naturally sourced yarn: RadiciGroup launches Biofeel® Eleven

RadiciGroup, the only European producer of this material, has chosen the "Performance days" trade fair (that took place in Munich on 15 and 16 March) to unveil this yarn with excellent technical and environmental performance.

At Performance Days, the new sustainable product for luxury garments, sportswear and workwear

Today, 80% of the world's castor-oil plantations are in India , particularly in the Gujarat region, due to its favourable climatic conditions. In this area, local people can earn an additional income by cultivating semi-arid land that does not compete with food production, and by applying the skills they have acquired over time to this work. Over the years, thanks to research, development and innovation in the value chain, the seeds from which the oil is produced have been selected and certified to ensure the finest quality, also in terms of end uses.

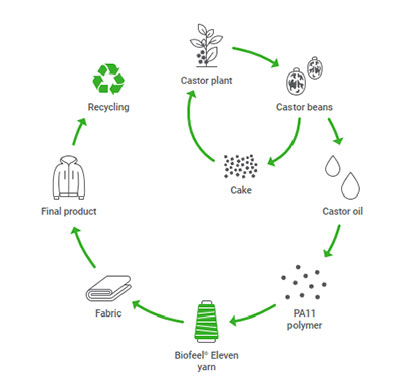

Castor beans contain around 45% oil, rich in ricinolein, from which the bio-polymer polyamide 11 is derived. This is the polymer RadiciGroup uses for its Biofeel® Eleven yarn. What remains after the first pressing is a highly effective bio-fertiliser that is returned to the soil. In short, a true example of circularity and “zero waste”.

"Biofeel® Eleven - underlines Marco De Silvestri, sales and marketing head of the Advanced Textile Solutions Business Area. - has unique and special properties, such as low water absorption, increased lightness and improved strength properties. . This means being able to produce fabrics that are both durable and comfortable to the touch and skin. This translates into a wide range of applications, from sportswear to workwear, from fashion garments to textiles for luxury cars."

Biofeel® Eleven can also be solution dyed, i.e. dyed at the yarn production stage, saving a great deal of water and energy and also providing greater colour stability.

100% bio-based and 100% recyclable, this yarn contributes to an increasingly sustainable textile sector that respects the principles of the circular economy.

""We have always stressed the importance of working as a team with all supply chain players, concludes De Silvestri - and we are delighted that Arkema, a multinational chemical company and our bio-polymer supplier, has chosen RadiciGroup as its exclusive European trusted partner to spin this valuable material. Biofeel®Eleven is not just yarn, it is a clear choice of environmental and social sustainability".

Significantly reduced CO2 emissions from Biofeel® Eleven have been demonstrated through the ISO 14040 based LCA* (Life Cycle Assessment) methodology, which scientifically, analytically and systematically measures the impact of a product throughout its life cycle.

*LCA study 2022 of Arkema polymer PA11