#Yarn & Fiber

Toray invents 100% bio-based adipic acid from sugars derived from inedible biomass, scaling up for application to eco-friendly Nylon 66

The company has started to scale up its capabilities in this area. It will test polymerization of nylon 66, develop production technology, conduct market research, and take steps to commercialize applications for this bio-based adipic acid by around 2030.

Nylon 66 has been used for many years in fibers, resins, and other applications due to its exceptionally durable, strong, and rigid properties. Pressures to develop eco-friendly nylon 66 have risen in recent years amid a growing awareness of the need to realize a sustainable society. One challenge is that conventional chemical synthesis for producing adipic acid, the raw material of nylon 66, generates a greenhouse gas called dinitrogen monoxide.

Toray was the first in the world to discover microorganisms that produce an adipic acid intermediate from sugars. The company reconfigured metabolic pathways within microorganisms to enhance production efficiency by applying genetic engineering technology, which artificially recombines genes to streamline synthesis in microorganisms. It also employed bioinformatics technologies to design optimal microbial fermentation pathways for synthesis. Quantity of the intermediate synthesized by microorganisms has increased more than 1,000-fold since the initial discovery, and the efficiency of synthesis has improved dramatically.

Toray is using reverse osmosis separation membranes to concentrate the intermediate in the purification process. This approach is more energy efficient than other methods that do not use these membranes.

This bio-adipic acid production technique is free of dinitrogen monoxide emissions, unlike the manufacturing processes for petroleum-derived adipic acid,?and is expected to help combat global warming.

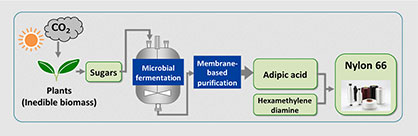

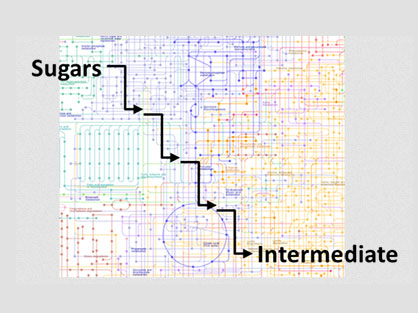

Overview of process, from inedible biomass-derived sugars to nylon 66

Toray is developing a process for producing sugars from crop residues and other inedible plant resources. Sugars from this process could be used as raw materials for bio-based adipic acid. Toray would thus be able to create a total supply chain to make chemicals from inedible biomass, helping pave the way to a circular economy.

Toray’s achievement is partly attributed to joint research with the National Institute of Advanced Industrial Science and Technology, and RIKEN, Japan’s largest comprehensive research institution. That effort is part of two projects that the three partners are undertaking with funding from the New Energy and Industrial Technology Development Organization. The first project is “Development of Production Techniques for Highly Functional Biomaterials Using Plant and Other Organism Smart Cells”, and the second ongoing project is “Development of bio-based production technology to accelerate Carbon Recycling”.

Under the Toray Group Sustainability Vision, the company aims to assist the international community pursue sustainable development by offering innovative technologies and advanced materials solutions. The new bio-adipic acid production technology is part of the Group’s drive to become carbon neutral by 2050 and should help the world overcome challenges in achieving circular economy.

Toray will continue to offer solutions through innovative technologies and advanced materials for better, more diverse lifestyles and sustainable societies.

Technology overview

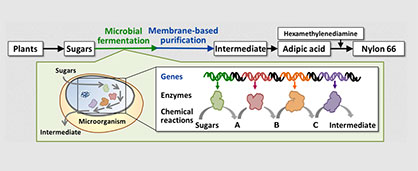

1. Microbial fermentation technology

Enzymes produced from microbial genes carry out chemical reactions to convert sugars into the intermediate.

(1) Genetic recombination technology

Allows deletion or insertion of genes for more efficient synthesis.

(2) Bioinformatics technology

Designing the optimal fermentation pathway by selecting the most efficient chemical reactions from all the available microbial metabolic pathways (consisting of several thousand reactions).

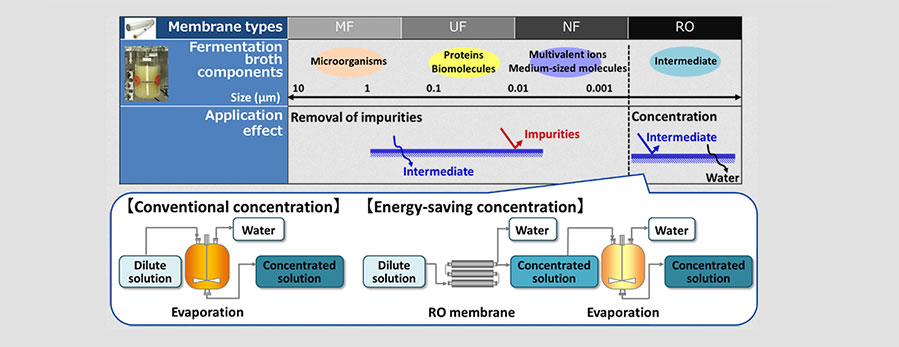

2. Chemical purification technology using separation membranes

Microfiltration, ultrafiltration, and nanofiltration membranes separate and remove unwanted components in microbial fermentation broth. Reverse osmosis membranes concentrate intermediates. Use of RO membranes can reduce energy consumption compared to conventional concentration by evaporation.

References

New Energy and Industrial Technology Development Organization-supported projects

- Funded project: Development of Production Techniques for Highly Functional Biomaterials Using Plant and Other Organism Smart Cells

https://www.nedo.go.jp/english/activities/activities_ZZJP_100118.html

- Demonstration project: International Demonstration Projects on Japan's Energy Efficiency Technologies/ Demonstration Project for an Energy-Saving Cellulosic Sugar Production System Using Bagasse

https://www.nedo.go.jp/english/activities/activities_AT1_00175.html

https://www.nedo.go.jp/english/news/AA5en_100389.html

- Toray’s water treatment membranes

https://www.water.toray/

- Toray’s New Frontiers Research Laboratories

https://www.toray.com/global/technology/organization/laboratories/lab_008.html