#Weaving

Tremendous interest shown in CREALET’S products during ITMA 2015 in Milan

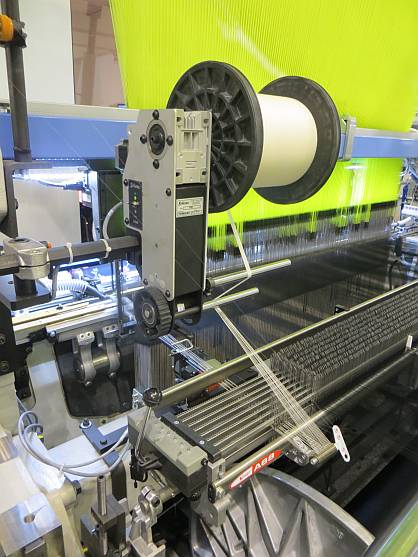

A broad portfolio of innovative solutions such as warp thread feeding, narrow and wide weaving machines, and warp knitting machines were presented.Items of particular interest to both visitors and the media were the innovative CS2 Selvedge Thread Let-off and the conversions from mechanical to electronic let-off for narrow weaving machines.

These new technologies replace conventional systems using a new independent control option. With these new innovations, users are given greater flexibility and can optimize their weaving processes more efficiently.

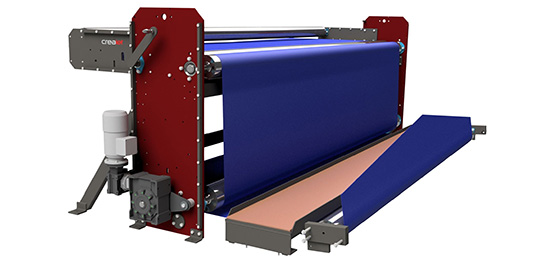

Visitors were also excited to learn about CREALET’s portfolio of products for wide weaving machines. These include conversion possibilities for Projectile Weaving Machines as well as the possibility of additional warp beam frames that can be placed behind either weaving or warp knitting machines.

Walter Wirz, General Manager of CREALET, was very positive about this year’s ITMA: “We had a highly successful ITMA 2015 with very positive feedback on the presented CREALET novelties. We have had very qualified discussions with numerous visitors and made many new contacts, thus strengthening our position as an innovative and competitive company.”