#ITM 2024

PICANOL to showcase the all-new ULTIMAX rapier weaving machine for the first time in Türkiye at ITM 2024

All of the innovations that will be shown are driven by Picanol’s four design principles: Smart Performance, Sustainability Inside, Driven by Data, and Intuitive Control. Together, these design principles enable Picanol’s customers to follow their weaving instincts and get the best possible results.

“With our strong presence at this exhibition, we once again want to make a clear statement on the importance of the Turkish market for Picanol and reconfirm our commitment to it. That said, we also hope to welcome customers and potential partners from other countries. Our team is looking forward to explaining to those visiting our booth about how our innovations will ensure we continue to grow together with the global textile industry and our customers in particular,” explains Mr. Kurt Lamkowski, Manager Worldwide Sales at Picanol.

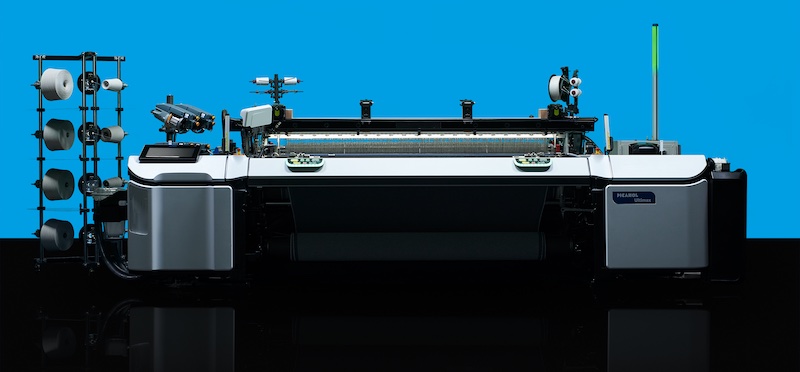

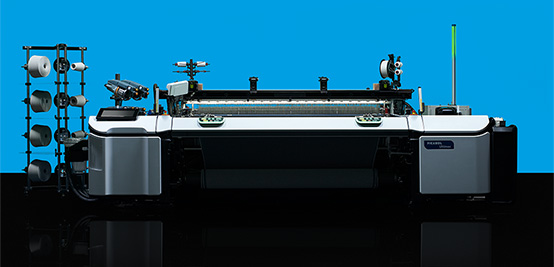

The all-new, revolutionary Ultimax rapier weaving machine

Picanol’s all-new and revolutionary rapier weaving machine, the Ultimax, focuses on three main benefits: ultimate performance and high-quality output, readiness for the sustainability requirements of tomorrow, and the greatest ease of use thanks to a maximum level of digitalization. In addition, the classic Picanol exterior design of the machine has been radically disrupted in order to make it clear from the outside just how revolutionary the Ultimax is on the inside. The Ultimax excels in the fields of performance and quality, it has been designed with sustainability as the baseline, and the high degree of digitalization results in a previously unseen ease of use. At ITM 2024, three Ultimax machines will be on display with different shedding motions, different machine widths, and a variety of features. One machine will be weaving denim fabric, another one will be weaving voile, and there will also be an Ultimax Terry.

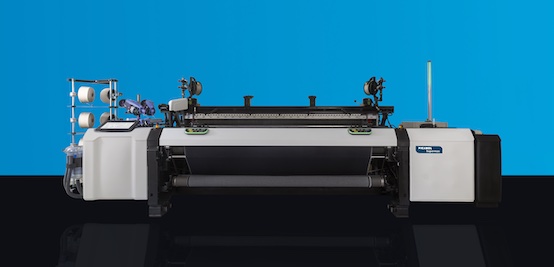

OmniPlus-i Connect airjet weaving machine

At ITM 2024, Picanol will be presenting an OmniPlus-i Connect airjet weaving machine with SmartShed, weaving double-face. Visitors can also experience the speed increase that Picanol recently launched on its airjet platform.

Digital innovations in PicConnect

With PicConnect, Picanol is centralizing its digital tools and services in one new fully digital platform. At a corner in the exhibition that will be dedicated to PicConnect, visitors will be able to discover all the benefits and latest features of PicConnect to leverage the full extent of the possibilities offered by Picanol weaving machines. Integrated machine manuals and tutorial videos, a central weaving styles management system, and enhanced machine stop insights are just a few of the new PicConnect features that Picanol recently released.

Details of the Picanol weaving machines that will be on display at ITM 2024:

1. Ultimax-4-R-2020 Denim

Warp: Co Ne 10/1

Density: 19 ends/cm

Drawing in width: 210 cm

Weft: PBT Ne 13/1

Density: 18.5 picks/cm

Highlighted features: Recycled yarn ready • EcoFill 4c • Electronic Right Gripper Opener (ERGO) • Gripper stroke measurement • Gripper tape monitoring • Guided Gripper GC • Quick Style Change (QSC)

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Gripper stroke measurement • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use • AutoSens filling detector • Gripper tape monitoring

Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation • on-loom Picascope

2. Ultimax-8-R-360 Fancy voile

Warp: Pes 68f24/800 den

Density: 30 ends/cm

Drawing in width: 336 cm

Weft: Pes 68 den + Pes 20 den + Pes 150 den + Pes 300 den + fancy Ne 1.8

Density: 18 - 28 picks/cm

Highlighted features: OptiForce take-up • QuickStep weft presenter • on-loom Picascope • Tension Display (TED) • Electronic Filling Tensioner (EFT) • SmartCut • e-Leno

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Gripper stroke measurement • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use • AutoSens filling detector • Gripper tape monitoring

Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation • on-loom Picascope

3. Ultimax Terry-8-R-260 Terry towel

Warp: Ground: Co Ne 20/2

Pile: Co Ne 24/2

Density: 23 ends/cm

Drawing in width: 251 cm

Weft: Co Ne 14/1 + Co Ne 24/2 + Chenille Ne 4

Density: 16 - 60 picks/cm

Highlighted features: Pneumatic pile backrest • Pile monitoring • Pile formation system • BlueTouch display • Guided Gripper GCv • Needle roller • Needle roll control

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Gripper stroke measurement • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use • AutoSens filling detector • Gripper tape monitoring

Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation • on-loom Picascope

4. OmniPlus-i Connect-4-D-220 Double face

Warp: Pes/El 75f72 den

Density: 60 ends/cm

Drawing in width: 200 cm

Weft: Pes/El 75f72 den

Density: 40 picks/cm

Highlighted features: BlueTouch display • SmartShed • Electronic Selvedge System (ELSY Plus) • BlueBox electronic platform • Blue22 EasySet prewinders • PosiJet

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use

Smart savings package: Power monitoring • AirMaster with integrated air consumption meter • Adaptive Relay Valve Drive (ARVD II Plus)

Optimization package: Pick Repair Automation (PRA II Plus) • Prewinder Switch-Off (PSO) • AutoSpeed • Harness frame stroke measurement & Shed simulation

5. PicConnect corner

Visit the PicConnect corner of the Picanol booth to discover everything you need to know about this platform. All of the Picanol weaving machines will be connected to PicConnect.

canva-900-1-1-1.jpg)