#Weaving

State Secretary Dr. Patrick Rapp and Member of the State Parliament Katrin Schindele visit Lindauer DORNIER in Esseratsweiler

On site, Schindele and Rapp witnessed the results of the latest investments at the Baden-Württemberg site of the internationally active machine and plant manufacturer. These include a new photovoltaic system on the roofs of the production halls where DORNIER manufactures innovative solutions for manufacturers of films and fibre composites. Since this year, the 4,000 square meter solar plant not only supplies the factory itself with renewable energy, but also feeds electricity into the public grid. "The fact that DORNIER is investing here in Esseratsweiler on a large scale in CO2 reduction and sustainability proves the future orientation and loyalty to the location of the traditional family business," said Patrick Rapp during his visit. State Secretary Rapp was also pleased that DORNIER continues to manufacture its machines and lines, which are exported to customers all over the world with an export share of over 90 percent, completely in the Esseratsweiler and Lindau plants despite the difficult general conditions. Of particular interest to the guest were the film production lines, up to 150 meters long, on which customers of Lindauer DORNIER produce films for food packaging, pharmaceutical products and special films for solar modules and capacitors.

Automotive suppliers could serially produce lightweight components on DORNIER systems

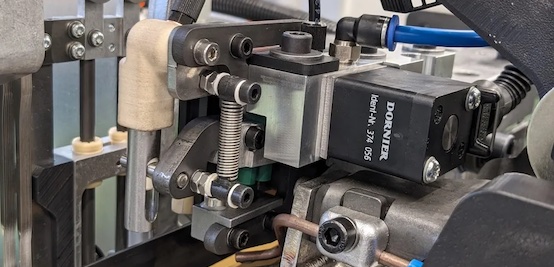

A visit to the Composite Systems Division's technical centre was also made on site. Here DORNIER develops and builds modern plants for the production of fibre composites. The lightweight components, which are produced on the machines by hidden champions all over the world, some of them highly specialized, can be found in aircraft and high-performance passenger cars. In the medium term, the traditional automotive supply industry could also use these machines for large-scale production. "Automotive suppliers could use them to mass-produce fibre composite components on demand for OEMs or TIERs – with the desired geometry, the right mix of fibres and matrix, and individual mechanical properties," said Dr Josef Klingele, head of the Composite Systems product line, during the tour. Because electric cars require fewer precision parts made of metal than petrol cars, Klingele said, capacities are freed up at medium-sized suppliers – these could be absorbed by the production of fibre composite components. "An automotive supplier that today turns injection nozzles or lasers sheet metal parts could in future increasingly produce fibre composite components on our systems," stated Klingele. This would preserve the distribution that has proven itself over decades: OEMs produce the large-scale series, while medium-sized companies with an affinity for development optimise the car components in terms of geometry, performance and costs. "Whether it's an electric car, a transport drone or a flying taxi – with our machines and systems we want to enable suppliers to creatively produce lightweight applications using standardised materials" said Klingele.

The topic was of particular interest to Katrin Schindele, a member of the state parliament who also worked as a development engineer at an automotive supplier before her political career. "It never ceases to fascinate me what you get to see in terms of creativity and performance when you visit family businesses in our region," said Schindele.

Largest investments in recent company history?

In the coming years, the family-owned company plans to continue investing massively in sustainability, energy efficiency and digital transformation. Franz-Peter Matheis, Commercial Managing Director at DORNIER, said during the tour: "We are currently making the largest investments in our recent company history in order to make our Esseratsweiler and Lindau sites even fitter for the future." In addition to the investments in the company's own power supply from renewables, he said, further ones are planned for the modernisation of the machinery, the optimisation of logistics and digitalisation. Andreas Kückelmann, Technical Managing Director at DORNIER: "With these measures we aim to navigate DORNIER through the current and future challenges." Because this also includes securing young talent, DORNIER held the DORNIER Talents Day at the Lindau site for the first time at the end of September. More than 200 young people and interested adults came to get an overview of the company's wide range of training opportunities, from industrial clerks to machining and construction mechanics to dual study programs.