#Weaving

Sharabati Denim confirms the trust in the Itema rapier technology and places an additional bulk order to the Italian company

Ever since committed to respecting environmental sustainability, Sharabati Denim introduced process optimizations to decrease water and energy waste and to promote responsible employment of chemicals. Fundamental driver of the mission of the Company is, in fact, the eco-centric approach which consists in a tireless pursuit of solutions for sustainable production with the aim of reducing the environmental impact to provide final consumers with sustainable fabrics.

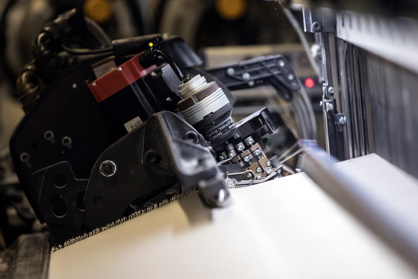

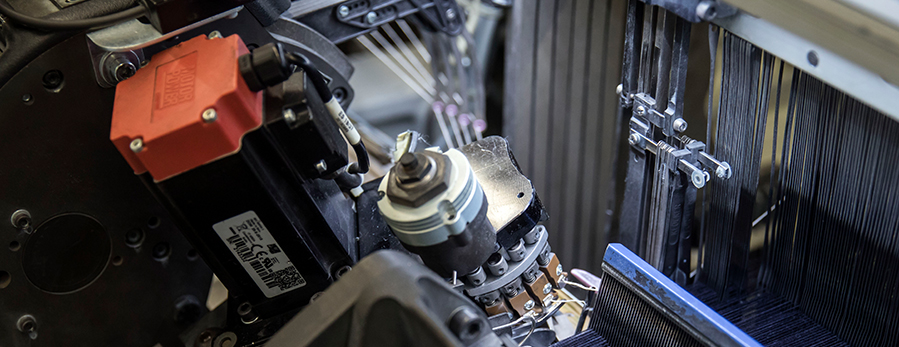

Precisely because of this vision, after the market launch in 2018 of the Itema rapier weaving machine exclusively dedicated to weave denim - the R9500-2denim, Sharabati Denim was among the pioneers to install a first group of this machine model, equipped with the one of a kind iSAVER®, the device that completely eliminates weft and warp waste on the left side of the fabric leading to significant cotton and water savings.

The R9500-2denim and iSAVER® performances were very satisfying– the best in their category – and led in 2021 to a repeat order both for the Egyptian and the Turkish plant for a total of more than 180 machines. Just consider that – as reported by the company – the iSAVER® equipped on the weaving machines in production ensures to Sharabati Denim a yarn saving that ranges from 650 Kg to 900 Kg per machine per year.

In 2022, Sharabati Denim implemented an expansion project aimed at significantly increase its production capacity. The weaving partner selected to provide 200 weaving machines for the Egyptian mill is Itema and, once again, its rapier R9500-2denim with iSAVER®.

With this last order, Sharabati Denim owns a fleet of more than 400 Itema rapier R9500-2denim, thus achieving outstanding levels of performances, sustainability and technological prowess. Sustainability and textile mastery are the added values that led Sharabati Denim to confirm the trust in the Itema weaving technology, also considering the significant enhancements introduced on iSAVER® also thanks to the fruitful cooperation between the two companies.