#Weaving

Swiss weaving machinery manufacturers are in the forefront of novel application development

Fabrics of the future…

These glimpses of the outlook for modern weavers are among the highlights of developments now being pioneered by Swiss textile machinery companies. All weaving markets require innovation, as well as speed, efficiency, quality and sustainability. Member firms of the Swiss Textile Machinery Association respond to these needs at every point in the process – from tightening the first thread in the warp to winding the last inch for fabric delivery. They also share a common advantage, with a leading position in the traditional weaving industry as well as the expertise to foster new and exciting applications.

Technology and research cooperation

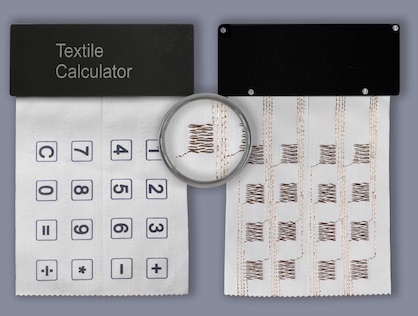

The concept of a ‘textile calculator’ was developed by Jakob Müller Group, in cooperation with the textile research institute Thuringen-Vogtland. Müller’s patented MDW® multi-directional weaving technology is able to create the meander fields which allow calculator functions to be accessed at a touch. A novel and useful facility, which suggests limitless expansion.

Today, the latest woven shoes are appreciated for their precise and comfortable fit. They score through their durability, strength and stability, meeting the requirements of individual athletes across many sports, as well as leisurewear. Stäubli is well known as a leading global specialist in weaving preparation, shedding systems and high-speed textile machinery. Its jacquard machines offer great flexibility across a wide range of formats, weaving all types of technical textiles, lightweight reinforcement fabrics – and shoes.

It’s possible to weave new materials such as ceramics, mix fibers such as aramid, carbon and other, and produce innovative multi-layers with variable thicknesses. Such applications put special demands on weaving machines which are fulfilled by Stäubli high-performance TF weaving systems.

Great weaving results are impossible without perfect warp tension, now available thanks to the world-leading electronic warp feeding systems of Crealet. Some market segments in weaving industry today demand warp let-off systems which meet individual customer requirements. For example, the company has recognized expertise to understand that geotextile products often need special treatment, as provided by its intelligent warp tension control system. Individual and connective solutions are designed to allow external support via remote link. Crealet’s warp let-off systems are widely used in both ribbon and broadloom weaving, for technical textiles applied on single or multiple warp beams and creels.

Functional, sustainable, automated

Trends in the field of woven narrow fabrics are clearly focused on functionality and sustainability. The Jakob Müller Group has already embraced these principles – for example using natural fibers for 100% recyclable labels with a soft-feel selvedge. It also focuses as much as possible on the processing of recycled, synthetic materials. Both PET bottles and polyester waste from production are recycled and processed into elastic and rigid tapes for the apparel industry.

For efficient fabric production environments, it is now recognized that automated quality solutions are essential. Quality standards are increasing everywhere and zero-defect levels are mandatory for sensitive applications such as airbags and protective apparel.

Uster’s latest generation of on-loom monitoring and inspection systems offers real operational improvements for weavers. The fabric quality monitoring prevents waste, while the quality assurance system significantly improves first-quality yield for all applications. Protecting fabric makers from costly claims and damaged reputations, automated fabric inspection also removes the need for slow, costly and unreliable manual inspection, freeing operators to focus on higher-skilled jobs.

Smart and collaborative robotics (cobots) offer many automation possibilities in weaving rooms. Stäubli’s future oriented robotics division is a driver in this segment with first effective installations in warp and creel preparation.

Control and productivity

Willy Grob’s specialized solutions for woven fabric winding focus on reliable control of tension, keeping it constant from the start of the process right through to the full cloth roll. Continuous digital control is especially important for sensitive fabrics, while performance and productivity are also critical advantages. In this regard, the company’s large-scale batching units can provide ten times the winding capacity of a regular winder integrated in the weaving machine.

The customized concept by Grob as well as design and implementation result in great flexibility and functionality of the fabric winding equipment – yet another example of Swiss ingenuity in textile machinery.

There is even more innovation to come in weaving – and in other segments – from members of the Swiss Textile Machinery Association in future! This confident assertion is founded on an impressive statistic: the 4077 years of experience behind the creative power of the association’s member firms. It’s proof positive that their developments grow out of profound knowledge and continuous research.