#Weaving

Steven – tradition meets precision

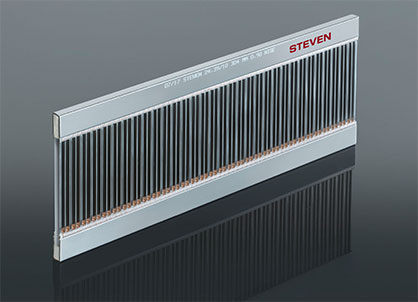

Even minimal deviations lead to mechanical or visual errors in the woven fabric. Because the reed touches each individual chain and weft yarn in the fabric, the smallest errors in the reed can lead to damaged filaments or broken warp threads. The reed thus affects not only weaving quality, it also has a significant influence on the productivity of the entire weaving process.

As the CEO of Steven Reeds GmbH, Michael Schmidt is responsible for the entire reed manufacturing process. In the interview, he speaks about the challenges brought on by extraordinary requirements for precision and quality and the benefit from this to you as a customer.

“With Steven Reeds, the influence that the reed really has is evident.”

Mr. Schmidt, what actually makes a reed from Steven Reeds so special?

Steven has manufactured reeds for the weaving industry since 1844. The manufacturing of reeds is strongly influenced by the human factor. This means that Steven reeds are unique not only because of the combination of the latest CNC production technology and materials of the highest quality, but also because of the decades of experience of our employees, their skill, diligence, and exceptional quality awareness.

Steven is focused on production technology, material, and know-how. Can you give us some detailed insight here?

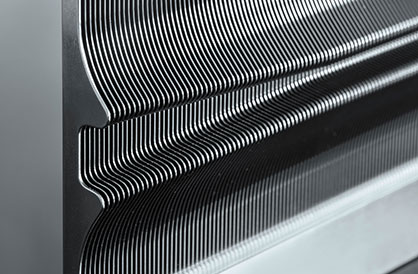

We rely on high-quality stainless steel for both our flat reeds as well as our air jet weaving machines. Thousands of rods make the edge rounding and finish quality perfect. We offer martensitically hardened steel for long service lives and high deformation stability. In addition, we employ a special finishing process for especially sensitive yarn.

The homogeneity, that is to say maintaining a uniform cut, rod for rod, gap for gap, is an important quality characteristic of our reeds. We achieve this through production processes using the latest CNC sheet binding technology. Furthermore, we measure and calibrate in order to provide uniform impact pressure for self-developed systems and deliver every channel reed with its own impact pressure protocol.

State-of-the-art sheet binding technology can support, but not replace, qualified employees. Which is why we rely on qualified employees with many years of experience in their work. We require and promote quality awareness and diligence.

If every customer has different needs, how do product specifications matter?

That is true. As opposed to accessories like healds or drop wires, reeds depend on the application. This means that, for every new woven fabric, the weaver normally needs a reed that is specifically designed for this fabric.

The specification process for the reed is the cornerstone of it functioning perfectly in the application. The weaver specifies a fabric by the number of warp threads and the threads per gap, resulting in the fineness of the reed. For the same fineness, the selection of rod thickness influences both the gaps as well as the stability of the reed. The gaps must be designed so that the threads have enough room but can still be guided cleanly. At the same time, the correct rod thickness must be chosen so that the reed is sufficiently stable for high weft numbers. Frequent warp thread breakages, filament damage, strong linting, and uneven weave patterns caused by clamping or feeding warp threads are typical characteristics of inadequately designed reeds.

It is for this reason that we have worked closely with weaving mills for decades. With the application experience we have acquired, we assist our customers in defining specifications for their reeds for any application. Ongoing plausibility checks guarantee error-free, specified reeds.

In addition to quality and consultation – are there other important factors for success?

Yes, in addition to consultation and quality, we also provide short response and delivery times as well as our patented reliability. A reed that does not work can quickly become expensive. Our motto is: draw in, weave, done – because we have made the success of our customers our goal.

Machine adjustments are a giant topic in weaving. How important is this topic at Steven Reeds?

Very! Machine adjustments – and thus the productivity of the weaving process – are, for us, an important argument for our reeds. We can reduce adjustments due to warp thread breaks to a minimum with the reed specifications and edge and surface quality of our sheet rods. Problems in the weft yarn area, especially with channel reeds, are influenced by uniform and precise impact pressure.

Does Steven Reeds therefore have all the necessary skills to help customers be successful?

There are several factors for us: We not only rely on our experience from more than 175 years of company history, we also benefit from entirely new opportunities. By that, I primarily mean the strengths of Groz-Beckert. Joint trials at the Technology and Development Center, use of the materials and textile laboratory, or the global presence of Groz-Beckert's proven sales network are just some of the advantages that our customers enjoy.

Let’s say you have convinced me, and I want to equip my machine with Steven Reed, how do I approach you?

That is easy: You can reach us via email at info@steven.de or find our complete contact info at www.steven.de.

There you can also view our specification sheet for reeds and obtain additional information on our product range. Our colleagues at Groz-Beckert will also be happy to help – you can best reach them via email at contact-weaving@groz-beckert.com.

One final question, Steven Reeds was also represented at the Groz-Beckert Group’s booth at the ITMA; what customer feedback did you receive?

Many customers were excited to have a competent point of contact in the areas of weaving preparation, weaving accessories, cleaning and, now, reeds. In particular, we presented many ideas and suggestions for solving problems in the area of reeds at the ITMA. We also, of course, like to present these to customers and interested parties in a personal discussion.