Textiles & Apparel / Garment

Outlast® selected as top innovation F/W 2015/16

For eight years now, Outlast Technologies, market leader for textile temperature regulating phasechange materials (PCMs), is already working together with the Portuguese company A. Sampaio, a wellknownmarket leader for knitted fabrics. For the future sportswear market A.Sampaio has designedattractive, extraordinary Outlast® knits for the season Autumn/Winter 2015/16 and presents excitingfunctional Outlast® fabrics on upcoming ispo: The Outlast® polyester fabric (quality 58778: 60% Outlast®PES, 31% PES, 9% EA), which is plain outside and brushed inside (215 g/m²), has been elected by aninternational Jury at ISPO Textrends 2014 as TOP 10 WINNER for the category “second layer”.

“We are proud that we have been selected for the Top 10 with an Outlast® polyester fabric,” says João Mendes, Board member at A.Sampaio & Filhos - Textiles S.A., Santo Tirso/Portugal. “The inclusion of Outlast® PCM technology was of major importance for this award. Customers are showing enthusiasm on the possibility of using such intelligent fabrics in their product ranges.”

The Outlast® polyester filament features all positive characteristics of a conventional polyester fiber like low moisture absorption and a good ability to transport moisture, an improved wrinkle resistance, superior light, water and wind resistance as well as a high tearing and abrasion resistance, which secures an above average durability. Beyond that it offers the added value to balance temperature changes dynamically to offer an increased comfort factor keeping with the motto …not too hot, …not too cold ,…just right. Chilling and sweating are reduced; less sweat is produced due to the optimum climate regulation.

Fibers, fabrics and other component materials play an incredibly important part in the sporting goods industry presenting trends and developments that will not be available to consumers until about two years later. Despite this, it is hard for designers and product managers to source the latest developments. This is the reason why Ispo Munich decided to develop a new area showing the best available component products in a concentration. A jury of trend experts examined all entered products and selected up to 60 products with the highest degree of innovation.

Outlast® technology

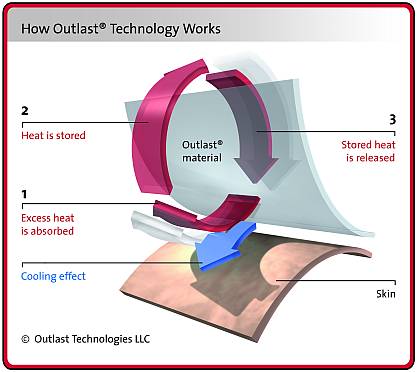

Outlast® technology was originally developed for NASA to protect astronauts from temperature fluctuations in space. Outlast® technology utilizes phase change materials (PCM) that absorb, store and release heat for optimal thermal comfort. Outlast® technology is comparable to ice in a drink; as it changes from solid to liquid, it absorbs heat and cools the drink, keeping that drink at the desired temperature for a longer period of time. Outlast® phase change materials work in the same way. The PCMs have the capacity to absorb, store and release excess heat. This gives any product containing Outlast® technology the ability to continually regulate skin’s microclimate. As the skin gets hot, the heat is absorbed, and as it cools, that heat is released.

Outlast® technology is not wicking technology, which manages moisture by reacting to your sweat and pulling it away from the skin. Outlast® technology will proactively manage heat while controlling the production of moisture before it begins. That’s the Outlast® difference. The benefits of Outlast® products at a glance:

- Absorbs excess body heat

- Manages moisture

- Reduces overheating

- Reduces chilling

- Reduces perspiration

- Continuously adapts to thermal changes

In times where competition is getting tougher, Outlast offers a true, winning benefit to its customers and retailers. They are able to offer an added value that improves comfort as well as increase the attractiveness of their line of goods. Experience has shown that PCM products have great sell-through and can drive an increase in sales. You can find A.Sampaio in hall C2, stand 335 at Ispo, January 26-29, 2014 in Munich/Germany.

Pic: Outlast® products can absorb excess heat, so the body doesn’t have to start sweating to achieve cooling. Outlast® technology is proactive and extremely hygienic: the production of sweat is reduced before it Begins.